Construction/Engineering

Automation equipment engineering (Mechatronics)

Achieving the early start-up of high-quality facilities with an integrated mechanical and electrical construction system

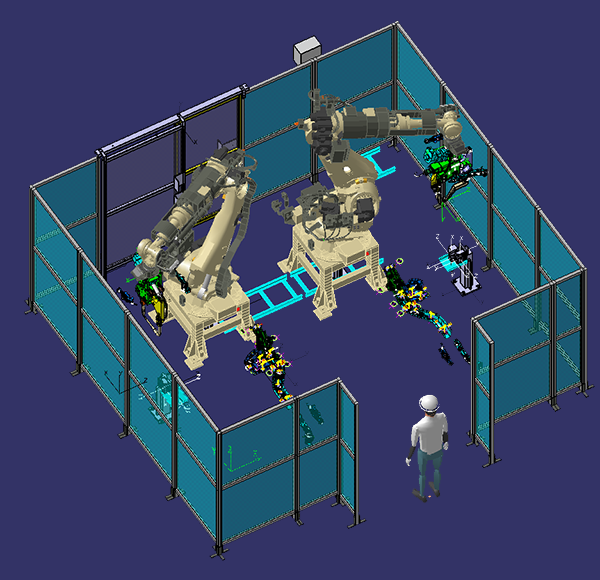

As an automotive automation partner, Mishima Kosan creates reference data for the entire process from 3D-CAD data to realize a highly efficient design process. Through solution design, adaptation studies, and off-line teaching enable us to smoothly reproduce high-quality equipment and products that meet customer's needs and enable early start-up.

Our products are carefully inspected with 3D measuring instruments to guarantee reliable quality and reduce labor costs and rework.

Automation equipment engineering of Mishima Kosan

Automation equipment 01Car production line

Automation equipment 02Steel production line

Automation equipment 03Others

Automation equipment 04Domestic locations and overseas delivery locations

Our specialty is here!

Integrated construction

Integrated construction from automobile production line design to on-site installation work

Consistent system

Consistent system from robot adaptation study, robot off-line teaching, 3D measurement, installation, and robot teaching

Digital analysis

Welding equipment capable of digital analysis

General industrial machine equipment

Design and manufacture of general industrial machine equipment (dedicated machine)

Maintenance

Maintenance, inspection and repair of existing equipment and robots

Automated and labor-saving equipment

We propose a wide range of jigs including body line welding jigs and robot hands, as well as automation and labor-saving equipment using robots and dedicated machines.

Automation equipment 01

Car production line

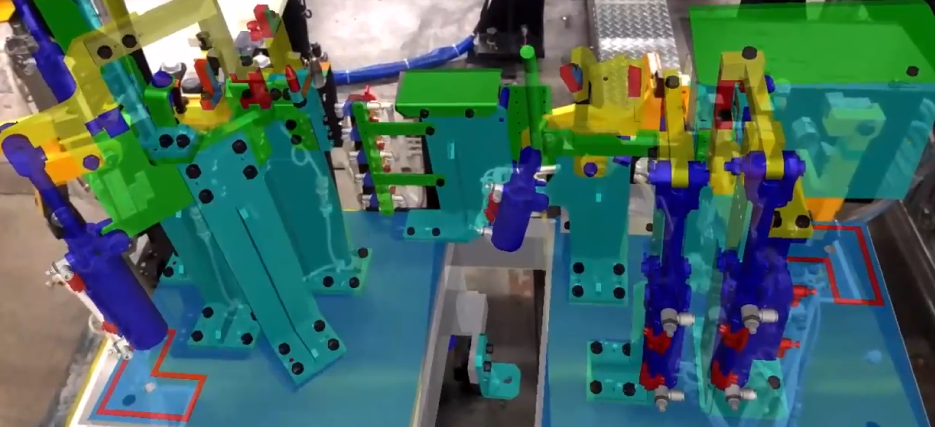

"Visualization of concepts" centered on 3D design

Non-stop even during model changes! Production processes remain in operational.

Mishima digital engineering brings production equipment to the customer accurately and speedily!

| Type | Monthly production capacity |

|---|---|

| Robot welding jig | 4 units (16 units/4 months) |

| Various transportation equipment | 1 line (4 lines/4 months) |

| Various dedicated equipment and tools | 4 units (16 units/4 months) |

| Facility modification work | - |

| Equipment maintenance | - |

Body welding system

Production flow

Mishima's digital engineering provides automotive production facilities with quick delivery and high quality.

- Jig layout plan

- Concept study/Jig design

Jig layout plan

Examination of jig

Jig design

- Mechanical/Control design

- Material procurement

/Parts processing - Assembly and electrical work

- Layout design

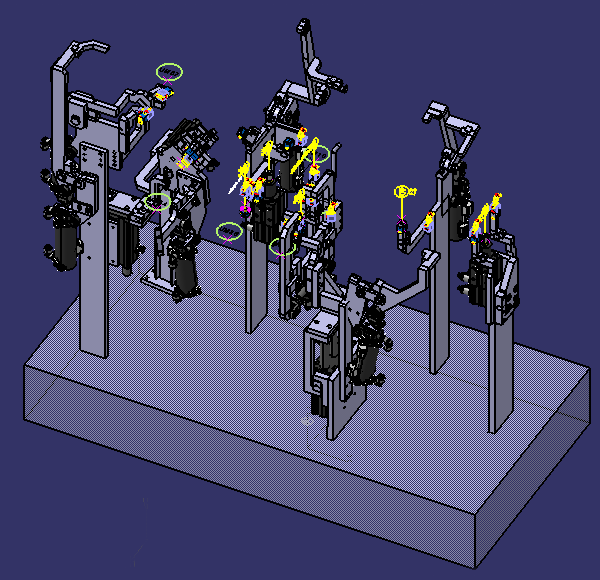

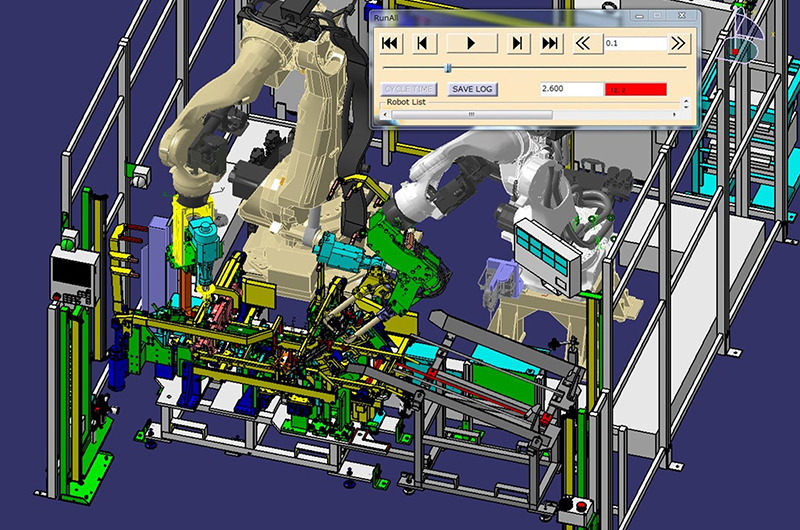

- Off-line teaching

Layout design

Examination of robot adaptation

Utilizing 3D-CAD, the robot simulation software will be used to examine the robot for movement and interference.

- Interference check (simulating the operation of the actual equipment on a computer to check interference and malfunctions in advance)

- Checking the motion area and motion trajectory (checking the robot's motion range) minimizes each motion range.

- Confirmation of cycle time (time from start to completion of equipment)

- Confirmation by off-line teaching (simulation of actual robot motion on a computer)

- Prevent manufacturing error by verifying the process before actual production line is built.

- Shortened line start-up time

Interference confirmation

Off-line teaching/

Machine tact verification

- 3D Measurement

- Operation check/Trial run adjustment

- Customer confirmation

Robot teaching

Customer confirmation

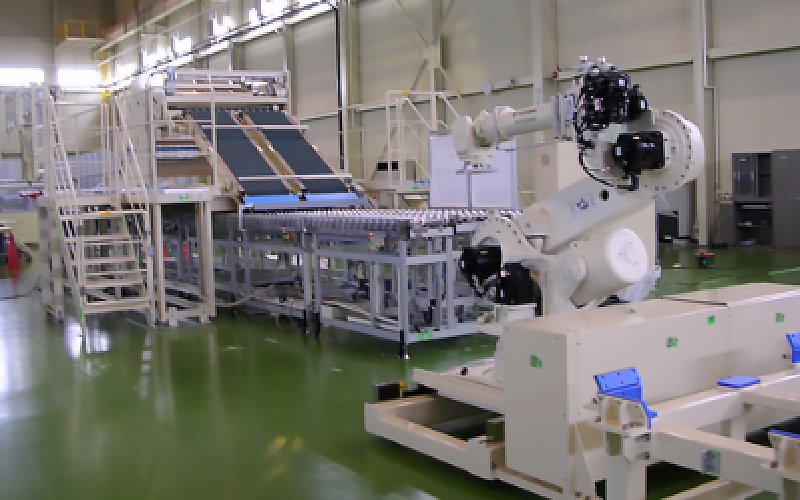

Automation equipment 02

Steel production line

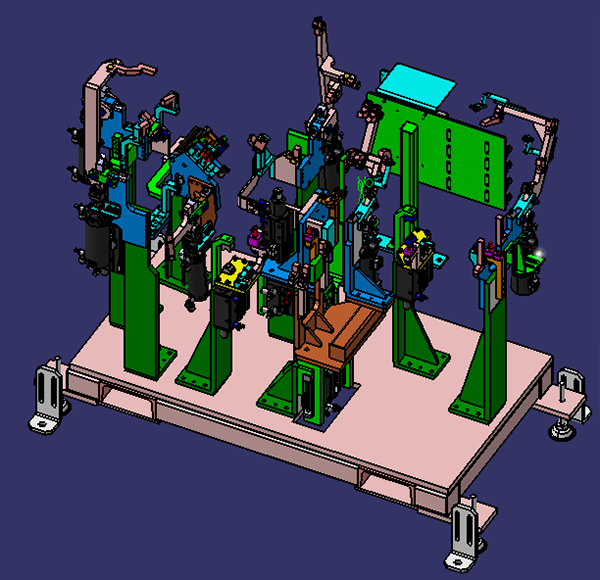

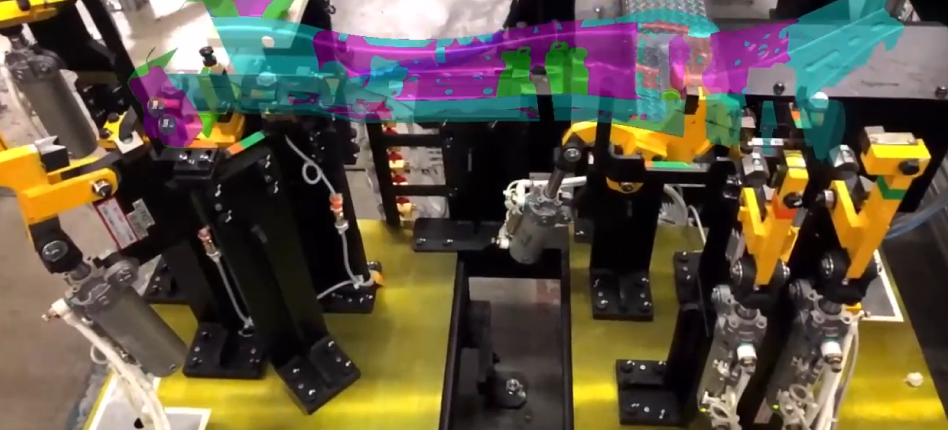

We provide the best systems to our customers by utilizing our many years of automation equipment engineering know-how in various industries.

With one-stop engineering that takes advantage of our expertise in automation equipment engineering, we support our customers' operations

with high-quality products with short delivery times.

Plant engineering powers up even more in collaboration with Mishima's digital engineering department!

Realizing quality and productivity improvement, we respond quickly from design to on-site construction, adjustment handover,

and after-sales service after delivery.

We ensure the safety of the customer's facilities and provide the system required by the customer under a consistent system.

- Consistent system from robot adaptation study, robot off-line teaching, 3D measurement, installation, and robot teaching

- Realization of flexible, efficient, high-precision and high-satisfaction products, including robots and special-purpose machines, by making full use of advanced mechatronics technology, from large to small.

- We propose a wide range of jigs such as welding equipment that can perform digital analysis and robot hands, as well as automation and labor-saving equipment using robots and dedicated machines.

- Design and manufacture of general industrial machine equipment (dedicated machine)

- Maintenance, inspection and repair of existing equipment and robots

Automation equipment 03

Others

many years of experience in automation technology

in various industries.

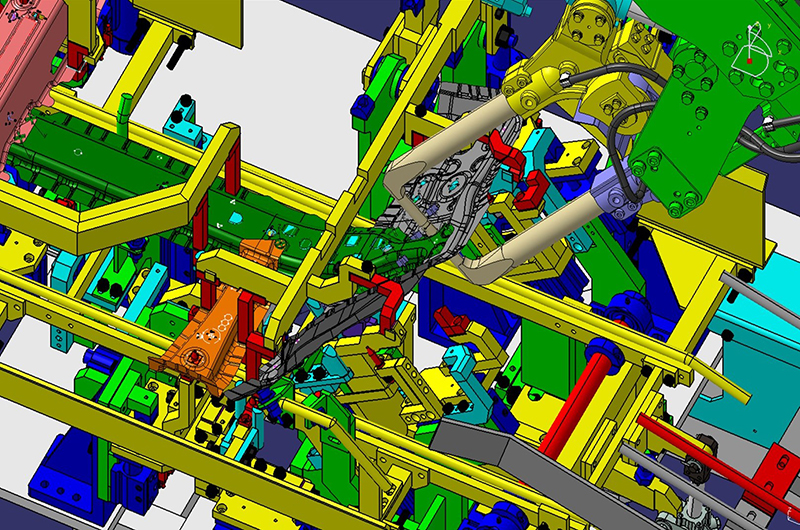

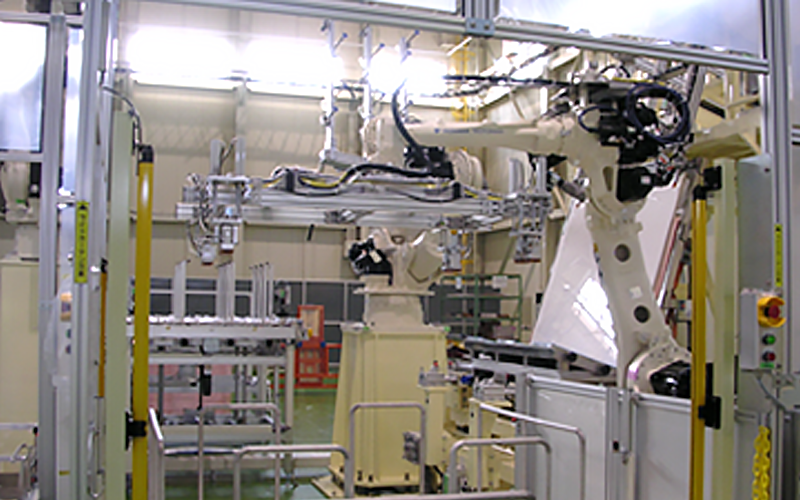

Based on many years of experience in automation technology in various industries, we improve quality and productivity and provide the system our customers require.

From design to on-site construction, handover of adjustments, and after-sales service after delivery, we respond quickly. We ensure the safety of our customers' facilities through a consistent system.

For advanced cleanliness requirements, a dedicated booth is installed in the factory!!

Equipment system suitable for clean environment

We meet our customers' clean quality requirements by providing a suitable environment for assembly, inspection, and packaging of equipment used in clean environments such as LCDs and semiconductors.

- Handling equipment that conforms to the clean environment of liquid crystal, semiconductor, and other manufacturing lines.

- Achieved unmanned, labor-saving operations that respond immediately to the age of FA.

- From large to small sizes, we make full use of advanced mechatronics technology to create flexible, efficient, high-precision, and highly satisfying products, including robots and special machines.

Case example of assembly environment

Consistent construction of design and production

A clean environment is achieved by installing filters in the factory.

For advanced cleanliness requirements, dedicated booths are installed in the factory to meet them.

A crane with a maximum weight of 10 tons is installed to effectively utilize the height of the factory to manufacture large products.

Please consult us first.

Diagonal board packing machine

Automation equipment 04

Domestic locations

and overseas delivery locations

and overseas delivery locations

but also overseas customers as guest engineers.

Domestic locations

Production sites

- Engineering Department

7-47 Shinsone, Kokuraminami-ku, Kitakyushu, Fukuoka 800-0211

TEL : +81-93-474-5840 FAX : +81-93-474-5847 - Tokyo Engineering Group

6-8 Chikumazawahigashi, Miyoshi Town, Iruma District, Saitama 354-0046

TEL : +81-49-265-3693 FAX : +81-49-265-5553