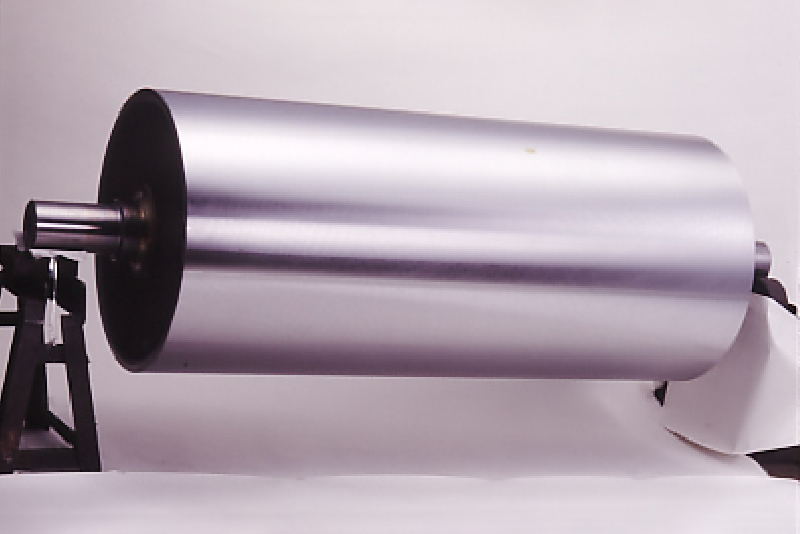

Roll

an integrated construction system.

We offer an integrated system from design to production and delivery of various roll products and parts.

In addition to conventional surface treatment technology, we respond to

the diverse needs of our customers with various original plating and thermal spraying that are excellent in corrosion resistance, wear resistance, and releasability.

Mishima Kosan roll products

Point01Providing high-quality and highly reliable roll products through consistent manufacturing

Point02Solving customer problems with optimal structural design and coating

Point03Surface treatment technology for a wide variety of applications

Point04High-quality plating is possible even for special materials

Point05Main facility list

Point01

Providing high-quality

and highly reliableroll products

through consistent manufacturing

and highly reliableroll products

through consistent manufacturing

From order receipt to delivery, we provide roll products that meet customer needs with thorough quality control and advanced technology.

Roll production flow

- Material arrangement

- Lathe processing

- Assembly

- Balance adjustment

- Grinding

- Plating

- Thermal spray

- Grinding

- Satin finish

- Roughness adjustment (shot processing, dimple processing)

Long rolls (max. length 10m) and large rolls (max. diameter 1.5m) can be handled!

see more- Size

- Surface roughness

- Balance

Point02

Solving customer problems with optimal

structural design and coating

structural design and coating

We propose the optimal structural design according to size and usage, and manufacture high-quality products that satisfy our customers, from surface coating to finishing (mirror grinding). Please contact us.

Roll body strength

With structural analysis, design the optimum structure of the roll body according to the usage environment and load.

Roll body cooling

For rolls used in high-temperature environments, we design the optimal cooling structure through heat transfer and fluid analysis.

Surface coating

Optimal coating specifications are designed according to the purpose and operating environment by combining our original coating technology with heat transfer and structural analysis.

Point03

Surface treatment technology for

a wide variety of applications

a wide variety of applications

We have our own equipment that can handle a wide variety of surface treatments to meet the needs of our customers.

Wear resistance

- Dimple crystal

- Crystal coat

- TCN Dimple thermal spray

Corrosion resistance

- Ni plating

- Electroless Ni phosphorous plating (Ni-P)

Releasability

- F. Hard

- Pinpoint smoother

- (super) Mirror surface, etc.

Long-lasting coating realized!

TCN Dimple thermal spray

(Original by Mishima Kosan)

We have put into practical use the thermal spray coating "TCN dimple thermal spraying" (Patent No. 6033991), which is an innovative idea that

has both excellent wear resistance comparable to conventional WC (tungsten carbide) thermal spraying and surface properties with

an indentation suppressing effect.

Life span when used on a certain company's line (actual results)

| Material | Lifespan |

|---|---|

| Conventional shot + Cr plating specifications | 3 months |

| Plating improvement dimple + Crystal | 6 months |

| WC Thermal spray | 9 months |

| TCN Dimple thermal spray |

4 times longer life than WC thermal spray!

36 months

|

Consistent construction of long rolls and large rolls!

Long rolls (max. length 10m) and Large rolls (max. diameter 1.5m) can be handled!

We perform consistent construction from base preparation to Cr plating to finish grinding.

Long roll

It supports long rolls with a max. length of 10 m, and has a track record of manufacturing high-performance film rolls.

Achievement

| Subject | Guide rollers, heating rolls, feed rolls, cooling rolls |

|---|---|

| Size | Φ200×5,200×6,068, Φ250×6000×7,591, Φ398×7,275×8,460, etc. |

| Max. weight | 2.5t (2.8t crane) |

| Material | Iron, stainless steel, aluminum |

Large roll

It supports large rolls with a max. diameter of 1.5 m, and has a track record of manufacturing steel and film rolls.

Achievement

| Related to steelmaking | Harth roll, conductor roll |

|---|---|

| Film related | Cooling drum, etc. |

| Size | Φ1,500×2,300, Φ1,300×2,210, Φ1,250×3,200 |

| Max. weight | 7t (7.5t crane) |

Longer high-performance film!

Addition of 10m long equipment!

(Newly established in December 2022)

High-performance films are functional films used in various fields such as electronics, automobiles, construction materials, pharmaceuticals, and food packaging. In addition to larger sizes, there is a demand for longer lengths and high-speed rotation.

Facility

・Cr plating bath size: ~Φ450×10,000

・Grinding machine workable size: ~Φ350×10,000

Horizontal rotary Cr plating machine No. 1

Total length 8m tank

Horizontal rotary Cr plating machine No. 2

Total length 10m tank

Long grinding machine No.1

Capable of grinding Φ600 x 8m in total length

Long grinding machine No.2

Capable pf grinding Φ350 x 10m total length.

W-head type capable of wet grinding and SF grinding.

possible to perform grinding regardless of material type.

Point04

High-quality plating is possible

even for special materials

even for special materials

In addition to various steel materials, we can plate special materials such as stainless steel, Ni, Cu, Al, and carbon (CFRP).

We can also handle other difficult materials. Please feel free to contact us.

Aluminum roll

Carbon roll

Point05

Main facility list

Roll plating equipment

| Type | Number of tanks | Workable size | Workable weight |

|---|---|---|---|

| Cr based plating bath | 9 tanks | Φ1,500×5,400 | 7 t |

| Horizontal rotating plating tank (Cr) | 2 tanks | Φ450×8,000 (Unit 1) Φ450×10,000 (Unit 2) |

2.5t |

| Ni-based plating bath | 5 tanks | Φ800×3,000 | 2.5t |

| Cu-based plating bath | 1 tank | Φ150×2,500 | 1t |

- The sizes shown are for tanks. Please contact us for product installation availability.

- Separate plating jig and tapped hole processing may be required depending on the shape of the product.

- It is also possible to reapply Cr plating (e.g. removing Cr plating).

- The weight is indicated by the rated load of the crane for the plating tank.

Roll grinding equipment

| Type | Number | Workable size | Workable weight |

|---|---|---|---|

| Large cylindrical grinder | 1 unit | Φ850×4,500 | 7 t |

| Cylindrical SF mirror grinding machine | 4 units | Φ1,000×5,000 | 3 t |

| Cylindrical dry buffing machine | 1 unit | Φ1,500×6,000 | 5 t |

| Cylindrical wet buffing machine | 3 units | Φ600×8,000 | 3 t |

Search in detail

Solution / Technical information

Main facility list

Main facility list

Here is a list of the main facilities we own.