Continuous casting mold/Mold

As a top manufacturer, we are promoting export and technology licensing from our domestic bases to overseas.

In 1968, we started Cr plating on the inner surface of billet molds at the Yawata Works of Nippon Steel Corporation (currently Nippon Steel Corporation Kyushu Steel works Yawata), and in 1971, we developed and successfully put into practical use Ni electroforming (thick plating), the first such process in Japan.

Since then, for more than 50 years, we have been designing, manufacturing, and maintaining molds, which are the heart of the continuous casting process, as well as peripheral equipment as the industry's top manufacturer. In recent years,

we have applied the technology we have cultivated over many years to enter the production of high-precision molds for automobile-related equipment.

Play the video about continuous casting mold [YouTube]

Continuous casting molds/Mold

Point01Achieving longer mold life and higher quality slabs

- Strengths of Mishima Kosan 1Optimization analysis/Design

- Strengths of Mishima Kosan 2Large surface treatment

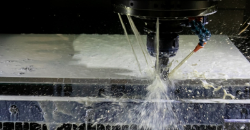

- Strengths of Mishima Kosan 3Large-scale machining and equipment assembly

Point02Providing highly reliable products with high-quality technology through consistent manufacturing

Point03Responding to the needs of customers around the world through overseas expansion

Pont01

Achieving longer mold life and

higher quality slabs

higher quality slabs

Along with remarkable progress in operating technology, the life of molds has increased dramatically, and the functions required for surface treatment have diversified.

Mishima's original (patented) mold that we developed, based on the highest level of manufacturing technology, continue to meet the needs of our customers by contributing to quality improvement and cost reduction through life extension in the steel industry.

Number of patents related to continuous casting (as of March 2021) 65

Mishima's original (patented) mold for high-quality, high-speed casting

Mold life (number of uses)

Trends by Age Group

Point02

Providing highly reliable products

with high-quality technology

through consistent manufacturing

with high-quality technology

through consistent manufacturing

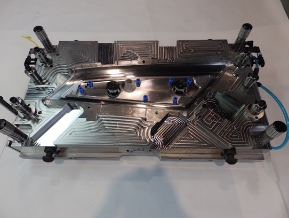

Our molds are manufactured consistently with our core technologies. We develop new products and technologies for plating and thermal spraying, design and analyze copper sheets and back frames, and provide products that meet customers' needs, including high-quality processing, surface treatment, and assembly technologies from large to small (SL, GB, BT) under optimal conditions to achieve them.

Mold production flow

Large-scale machining and equipment assembly

see more

MAW business

(Module Assembly Window)

Applying the core technology cultivated over many years to manufacture

highly reliable special mold products

Applying the design, analysis, machining, and assembly technologies we have developed over the years, we have also entered the mold business and developed it into MAW. We manufacture high-precision one-piece molds for automotive window glass and other products.

see more

Point03

Responding to the needs of customers

around the world through overseas expansion

around the world through overseas expansion

Our proud high quality and highly reliable products are exported not only to Asian countries but also to companies in Europe and America.

In addition, we are expanding overseas in various ways, such as licensing technology to overseas manufacturers and establishing locations, to meet the needs of customers around the world.

Provision of plating/thermal spraying technology, delivery of molds, overseas locations

Overseas location

Technology licensing

2016

Delivered large-scale plating equipment to Formosa Ha Tinh Steel Corporation (FHS) in Vietnam

Search in detail

Solution / Technical information

Main facility list

Main facility list

Here is a list of the main facilities we own.