Strength of Mishima Kosan 3

Large-scale machining and equipment assembly

We provide high-precision machining.

We are capable of cutting wide variety of metals, including iron, castings, copper, stainless steel, copper alloys, and aluminum, and we are particularly strong in the machining of large products such as plates and canning parts.

In addition to our original gantry-type machining center and deep hole drilling machine, we also have a horizontal boring machine, radial drilling machine, surface grinder, deep hole compound machine, etc., and we can process a wide range of sizes to meet your needs.

We also have "large", "medium", and "small" machines and cranes to handle various metal alloys and difficult-to-cut materials. From small products to large products up to 8m, we can meet the variety of customer needs.

Large-scale machining and equipment assembly

Point01Capable of handling small to large products

- Deep hole drilling machine (Mishima Kosan original)

- Five-sided double column machining center

- Simultaneous five-axis portal machining center

- NEWLaser tracker type non-contact 3D measurement system

Point02Capable of assembling large equipment and parts in a large assembly plant

Point01

Capable of handling small to large products

Main machinery and equipment

| No. | Item | Model | Manufacturer name | Max. work (t) | Max. processing range | ||

|---|---|---|---|---|---|---|---|

| L | W | H | |||||

| 1 | Five-sided double column machining center | MCR-BⅡ30X80E-A | Okuma | 52 | 8,000 | 3,050 | 1,750 |

| 2 | Five-sided double column machining center | MCR-BⅡ25X65E-A | Okuma | 34 | 6,500 | 2,550 | 1,550 |

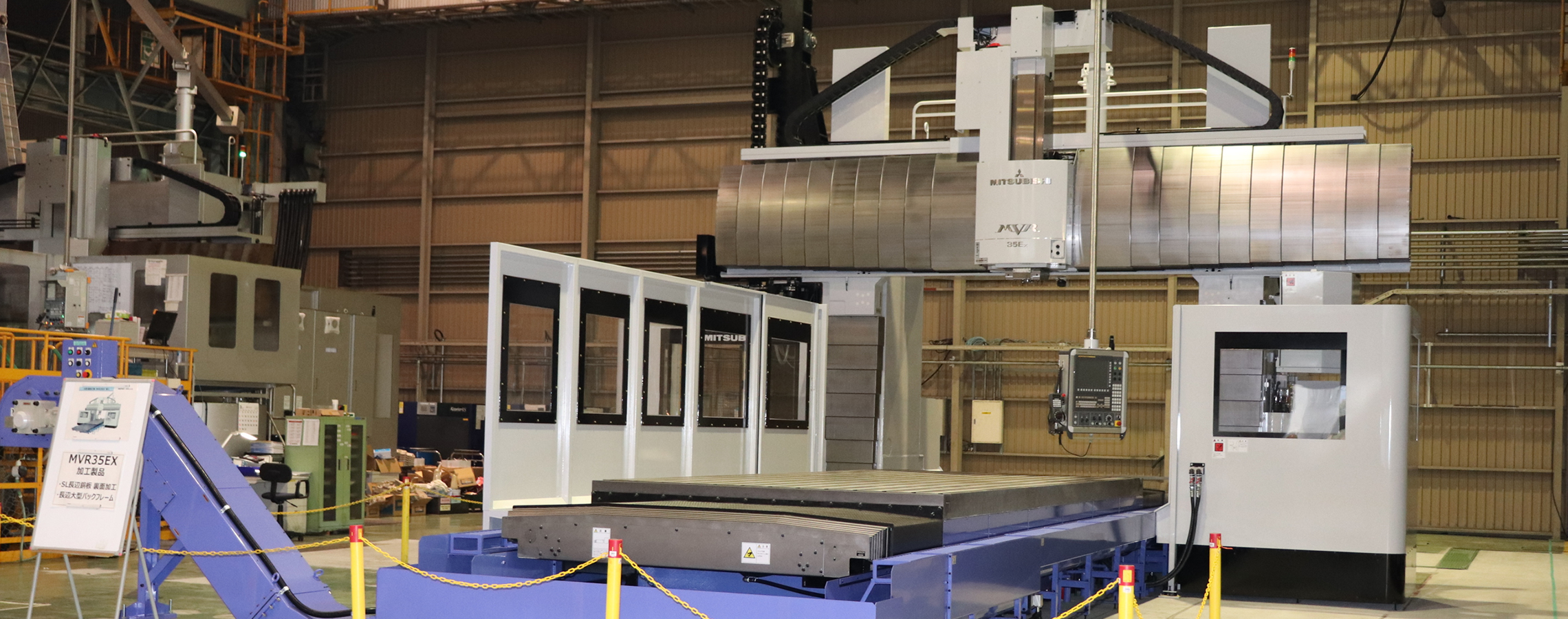

| 3 | Five-sided double column machining center | MVR-35Ex | Mitsubishi Heavy Industries | 30 | 6,200 | 3,500 | 1,850 |

| 4 | Simultaneous five-axis portal machining center | MVR-30FM | Mitsubishi Heavy Industries | 20 | 4,200 | 2,550 | 1,650 |

| 5 | Deep hole drilling machine | - | Mishima Kosan Original | 2.5 | 3,000 | 280 | 1,500 |

| 6 | Horizontal machining center | MCC2516 | Makino milling rice | 10 | 3,000 | 1,600 | 1,300 |

| 7 | Deep hole compound machine | MGC-315C | Toshiba machine | 6.3 | 2,000 | 1,400 | 1,600 |

| 8 | NC Horizontal boring machine | BTD-11R16 | Toshiba machine | 8 | 2,000 | 1,500 | 2,000 |

| 9 | Horizontal machining center | FH1250SX | JTEKT | 5 | 2,000 | 1,600 | 1,850 |

| 10 | Vertical machining center | VM-940R | OKK | 3 | 2,060 | 940 | 820 |

| 11 | 3-axis NC surface grinder | KSH-815 | Sumiju Fine Tech | 3 | 1,500 | 800 | 700 |

| 12 | Vertical machining center | VM7Ⅲ | OKK | 1.5 | 1,530 | 740 | 810 |

| 13 | Surface grinder | PSG-157DX | Okamoto Machine Tool | 2 | 1,500 | 700 | 600 |

| 14 | Surface grinder | PSG-157DX | Okamoto Machine Tool | 2 | 1,500 | 700 | 600 |

| 15 | Radial drilling machine | HOR-D2000 | OGAWA | - | φ1,620 | - | 1,275 |

| 16 | 850t Horizontal injection molding machine | - | - | - | - | - | - |

| 17 | Leica Laser Tracker Type Non-Contact 3D Measurement System | AT960・AS1・T-probe | Leica | - | - | - | - |

Horizontal machining center

MCC2516

850t Horizontal injection molding machine

High rigidity vertical machining center

VM940R

Fine deep hole processing machine (Mishima Kosan original)

Small deep holes with a diameter of 1 mm and a max. of 1,000 mm are possible.

Our original deep hole drilling machine is a processing machine specially designed for drilling small diameter holes.

This machine is capable of drilling holes even in very hard materials, and can drill small diameter and deep holes in a range where

cutting drills cannot be used, providing a good finished surface with special machines and technology.

Machine features

- Max. hole depth 1,000mm

- ATC device (automatic tool changer) supports unmanned machining (max. number of tool sets: 20)

- Large workpiece size is possible

- Please inquire about processing materials.

Target work

Max. processing size:

3,000L×280W×1,500H(mm)

| Hole diameter (mm) | Max. depth (mm) |

|---|---|

| φ1.0/φ3.0 | 1,000 |

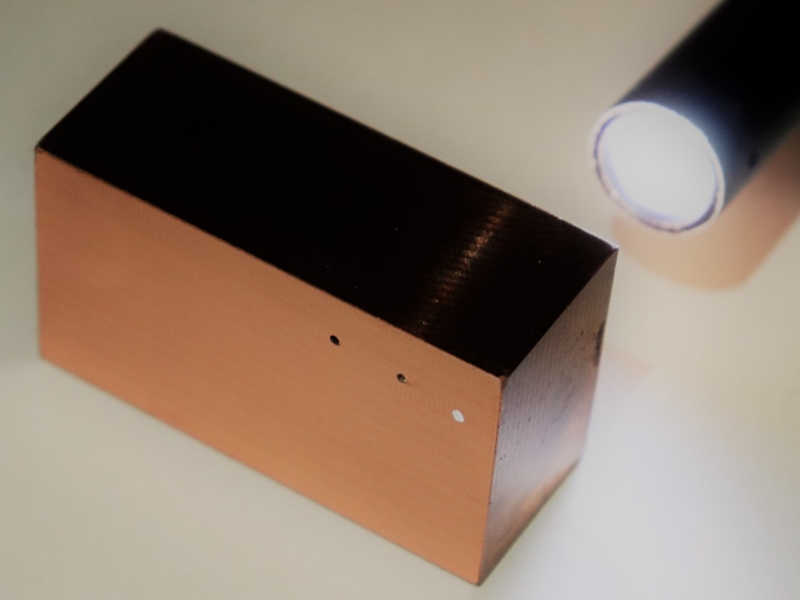

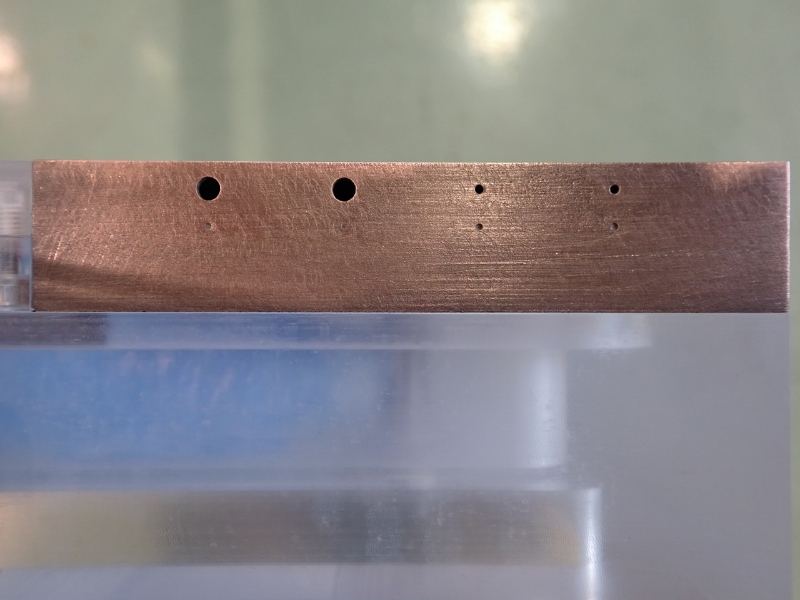

Processing sample

Processing sample

EDM samples for small holes

Five-sided double column machining center

Processing large metal products in various fields with the technology cultivated in mold manufacturing

With one-chuck machining (one process), stable and high-precision machining of right angles, hole pitch accuracy etc.,

of large molds and can products is possible.

Target work

Max. processing size:

8,000L×3,050W×1,750H(mm)

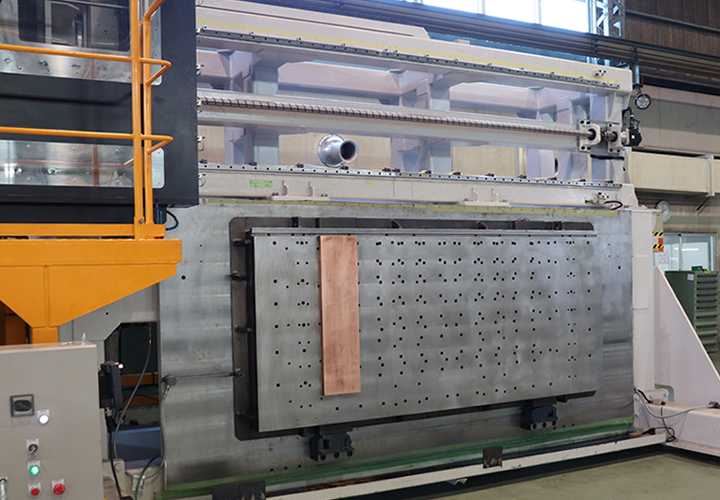

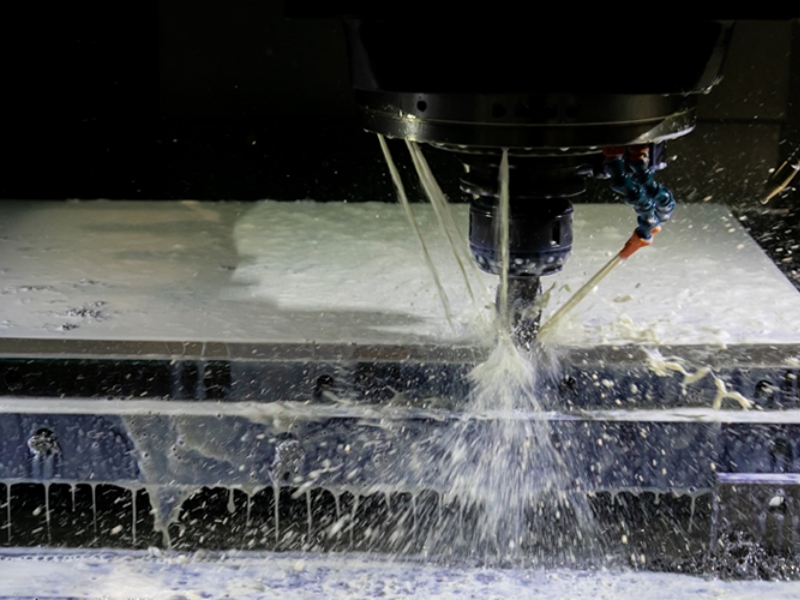

Processing scenery, processing sample

Processing scenery

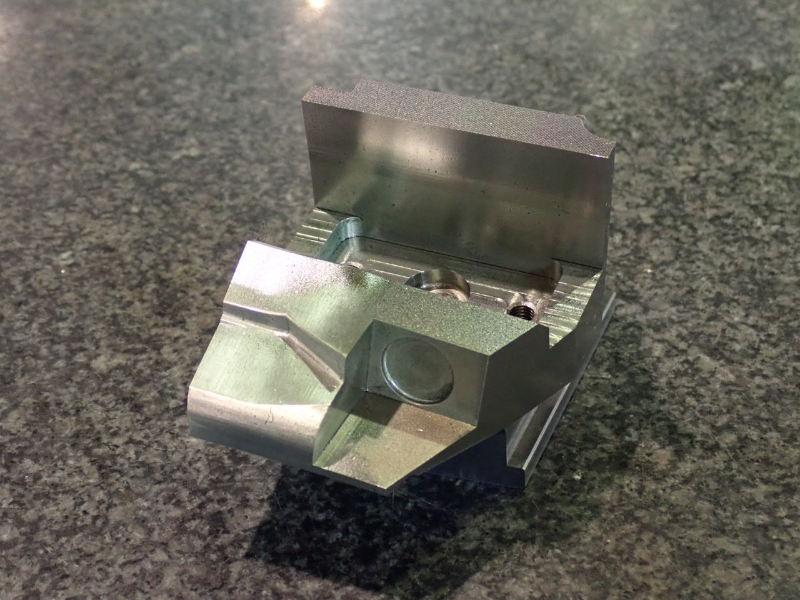

MVR35 machining sample

Simultaneous five-axis portal machining center

High-precision machining of free-form surfaces that cannot be machined with a 3-axis machine

Simultaneous 5-axis control machining center enables high precision and shortened machining time!

It can handle all kinds of inclined surface processing, such as cutting out shapes that are difficult and time-consuming with

conventional processing methods.

Target work

Max. processing size:

4,200L×2,550W×1,650H(mm) (Pallet change mechanism)

Processing scenery

Processing sample

MVR30 Machining sample

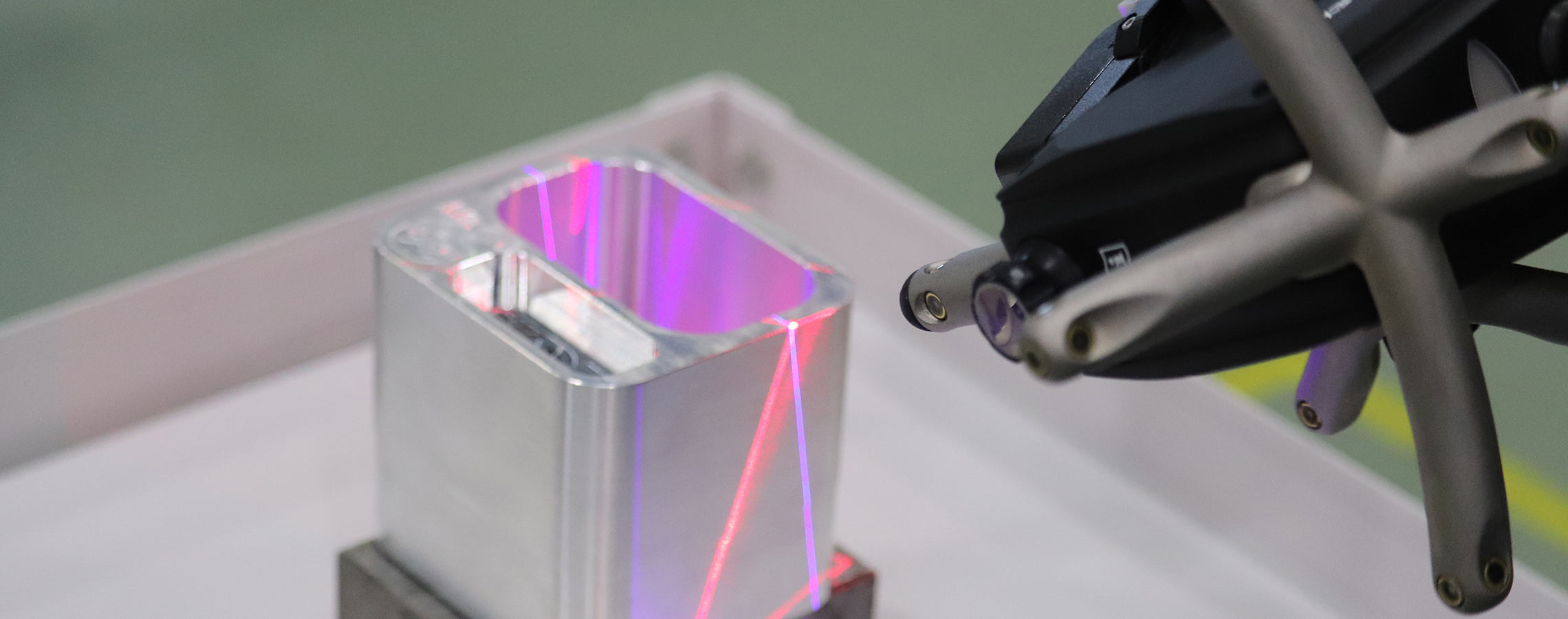

Leica Laser Tracker Type Non-Contact 3D Measurement System

High-precision measurement of a 20m diameter area with non-contact and contact capabilities, and 3D modeling is also possible!

- The process from measurement to output of result reports is automated, achieving efficient data processing.

- The mobile system enables non-contact measurement of large workpieces regardless of location.

- Measurement results can be verified in a short time using 3D dimensional analysis software.

Laser Tracker AT960

It is easy to carry, takes only a few minutes to set up, and can perform high-performance measurements anywhere. In addition to conventional reflector measurements, it is possible to perform non-contact 3D shape measurements using the handheld scanner (3 types) and 3D dimension measurements using the wireless probe T-Probe.

| Measuring range diameter | 20m |

|---|---|

| Measurement range (horizontal direction) | 360 degrees |

| Measurement range (vertical direction) | ±145 degrees/360 degrees |

| Protection rating | IP54 (dustproof/waterproof: IEC60529) |

| Measurement range | 1.5 to 20 m |

| Measurement accuracy (when using reflector) | ±15μm+6μm/m |

AS1 Scanner

Ultra-fast! This cutting-edge 3D scanner can collect data at up to 1.2 million points per second, can be mounted on industrial robots for full automation, and is a laser scanner that combines best-in-class accuracy and data quality.

| Measurement accuracy | ±50µm |

|---|---|

| Standoff (measurement distance) | 165mm±50mm |

| Minimum point pitch | 0.037mm |

| Maximum Sampling Rate | 1,200,000pts/sec |

T-Probe (touch probe)

When combined with a Leica laser tracker, it makes it easy to measure large areas that are difficult to reach.

| Measurement accuracy | ±35µm+reflector accuracy |

|---|

Measurement Scene

This video introduces the state-of-the-art non-contact 3D digitizer we use in our 3D scanning services.

The 3D shapes of complex or large parts can be scanned quickly and easily on-site to obtain highly accurate data. Even for parts that were difficult to measure using conventional methods, accurate quantified measurement results can be obtained in a short time. Furthermore, this data makes problems in each process visible, greatly contributing to quality improvement and process improvement.

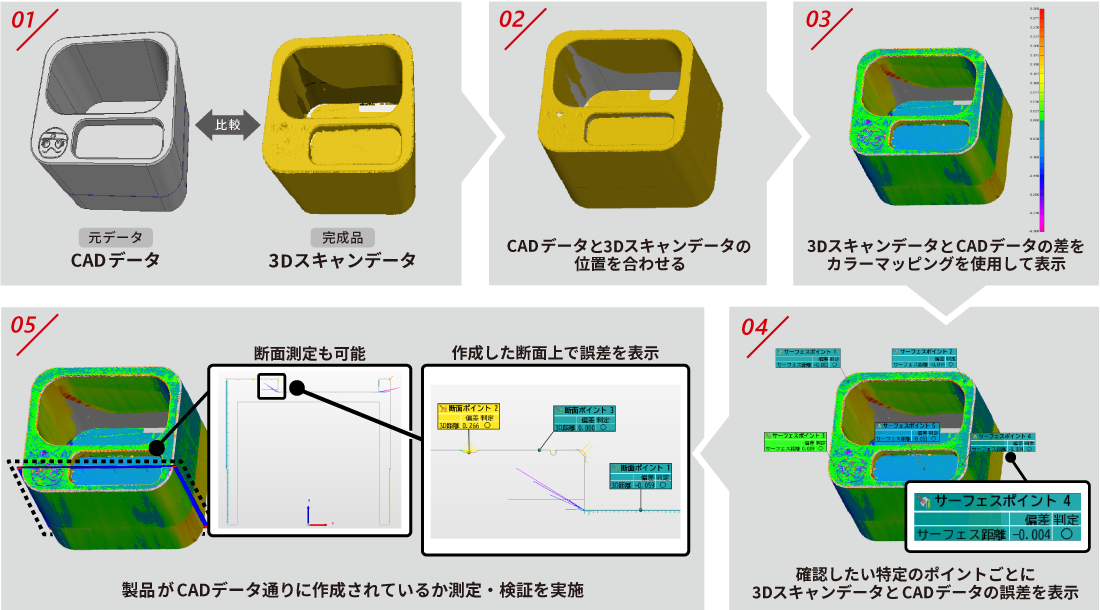

How to compare 3D scan data with CAD data

This diagram shows an example of how to use 3D dimensional analysis software to analyze, measure, and verify whether a product is made according to CAD data.

Point 01Products with complex shapes and sizes can be measured quickly and verified with highly accurate data comparison!

By comparing the 3D scan data with CAD data using 3D dimensional analysis software (PolyWorks Inspector), the quality of the product can be confirmed on the data. Non-contact measurement of large workpieces is also possible, and products that were difficult to measure using conventional methods can be compared with high precision in a short time. This process allows us to check even minute errors before delivery, allowing us to deliver more precise products to our customers.

Point 02Rebus engineering is also possible!

Even for products for which we do not have accurate drawings, we can create CAD data and produce 3D models by using a Leica laser tracker-type non-contact 3D measurement system.

Point02

Capable of assembling large equipment

and parts in a large assembly plant

and parts in a large assembly plant

Our highly skilled engineers with large-size assembly technology complete the product and deliver it to the customer with peace of mind through thorough quality control. We have a large crane and can handle large products up to 30 tons.

Owned crane capacity/Number

| Lifting capacity | Number |

|---|---|

| 5t to 30t | 12 units |

| Less than 5t | 16 units |

Distortion correction

Search in detail

Solution / Technical information

Main facility list

Main facility list

Here is a list of the main facilities we own.