Construction/Engineering

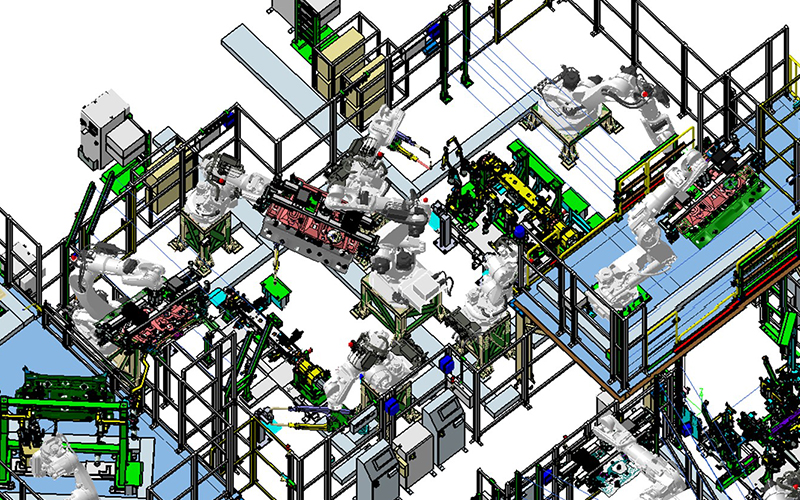

Case examples of automated equipment

Automobile/Steel production line

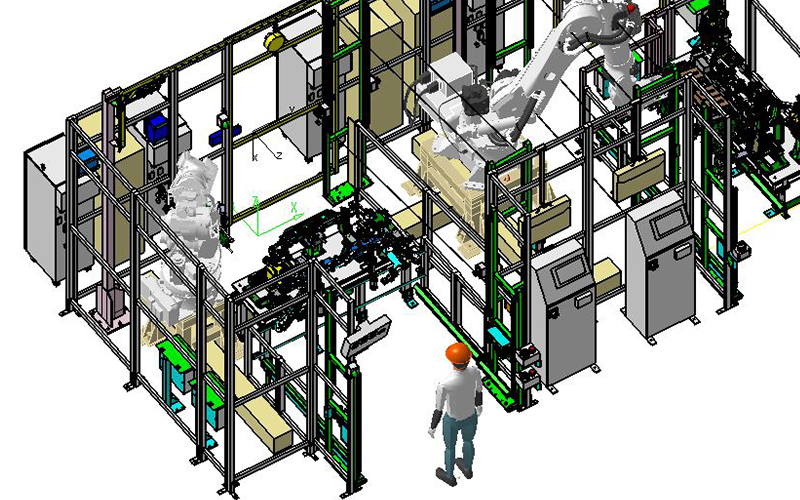

Achieving early local start-up of high-quality automated facilities that meet customers' needs!

As an automotive automation partner, Mishima Kosan provides high-quality automation equipment that meets customers' needs to solve problems in automotive production lines, such as automation and cycle times reduction.

Solution design and adaptation studies using 3D-CAD data, off-line teaching, and 3D measurement and inspection enable early start-up of high-quality automated equipment.

Case example of automated equipment (automobile/steel production line)

Case example 01Automotive welding equipment (large) (medium)

Case example 02Bolting fastening+ Handling

Case example 03Automobile-related jigs (rotating jigs)

Case example 04New transfer system for automobiles (wire transfer)

Case example 05Auto parts equipment

Case example 06Primer application/Heating furnace C/V

Case example 07Auto glass equipment (molding hand)

Case example 08Unmanned by robots

Case example 09Conveyor/Storage related

Case example 10Steel production line equipment

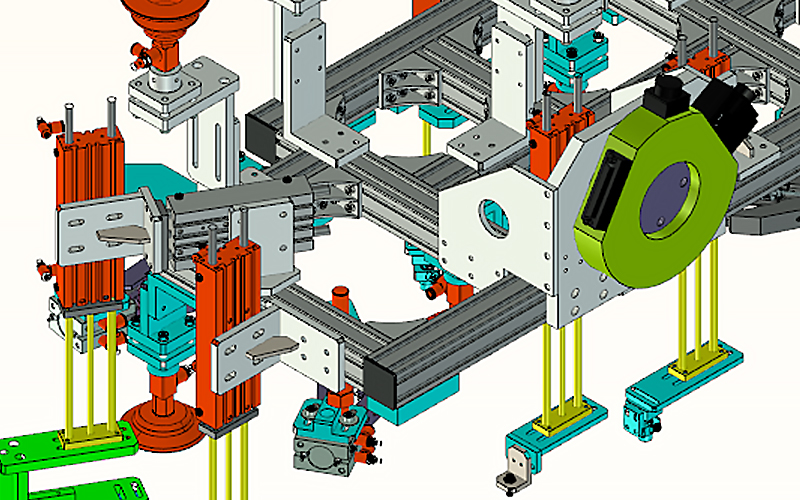

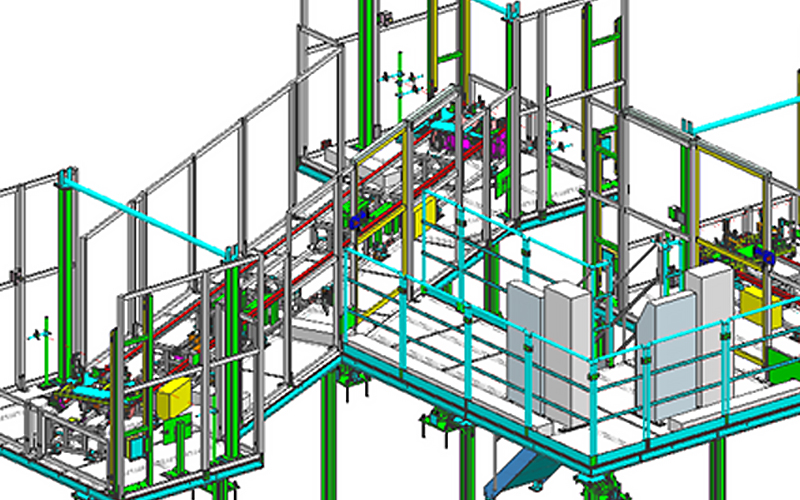

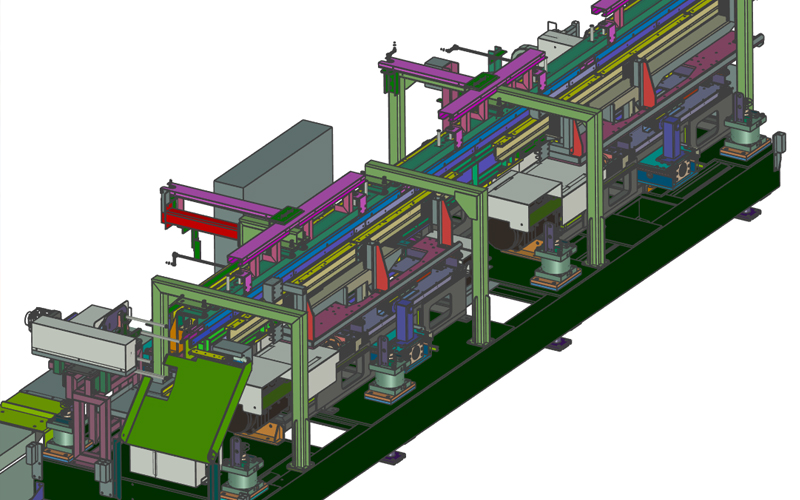

Installation image

In-house photo

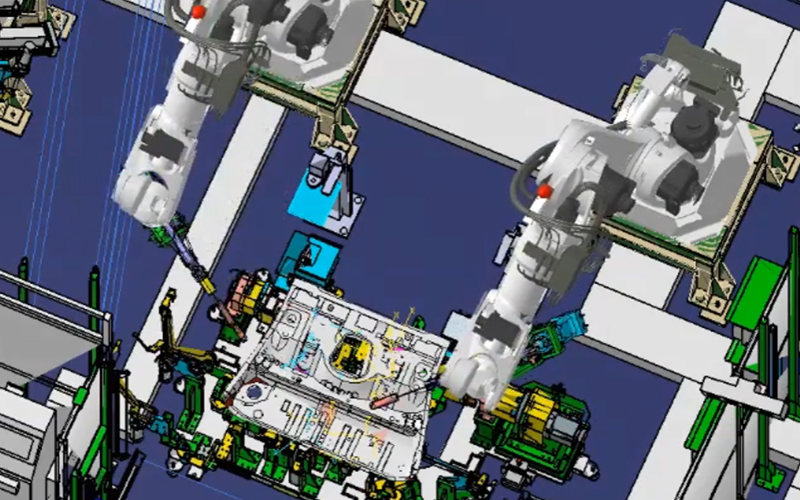

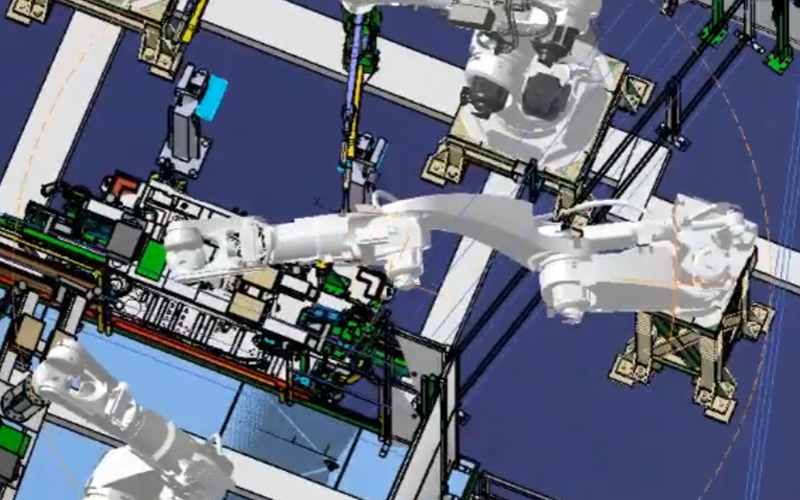

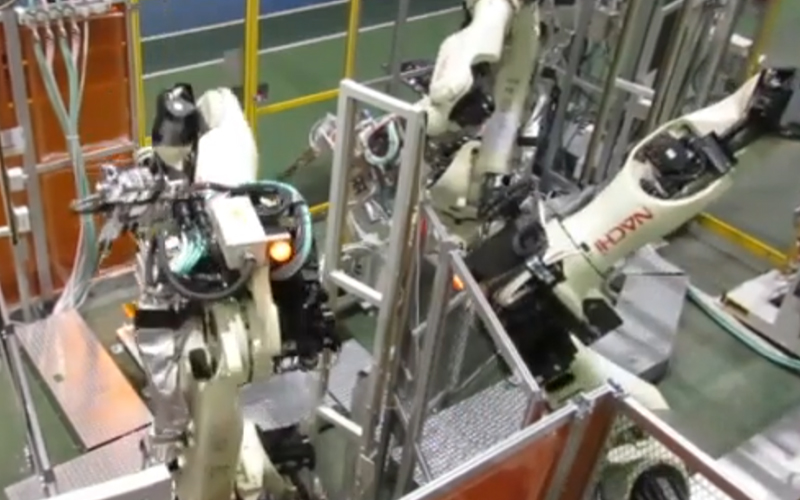

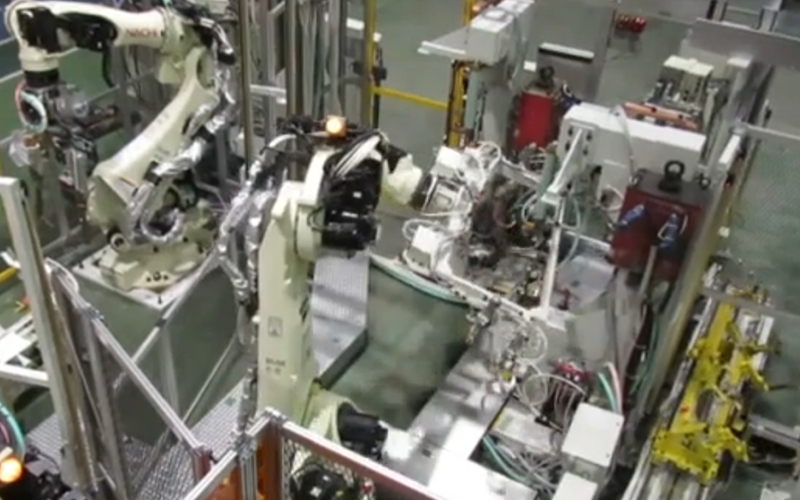

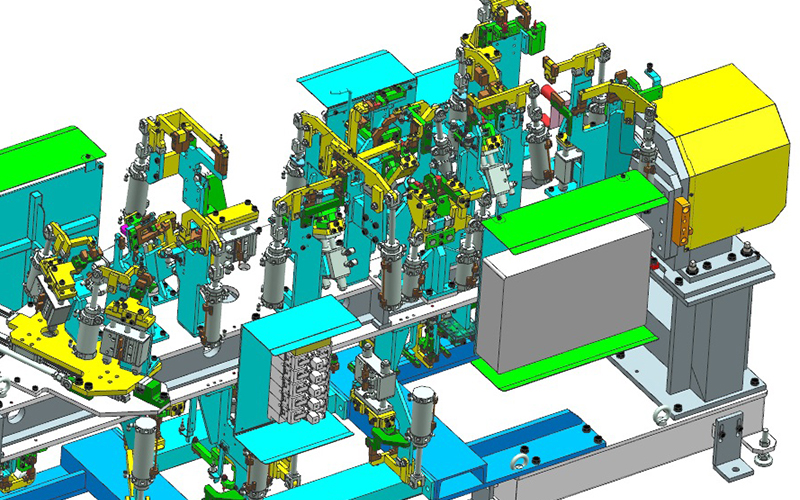

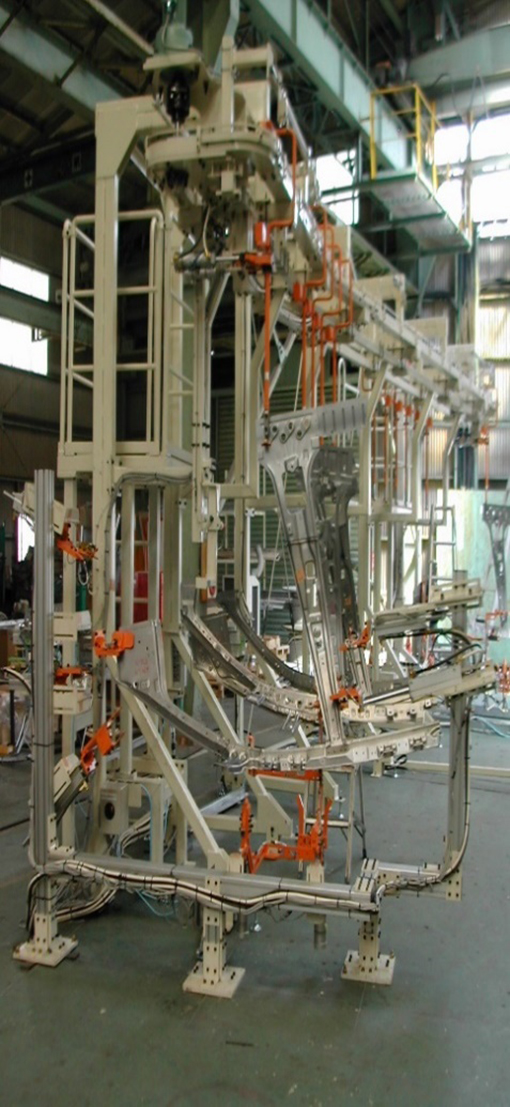

Case example 01

Automotive welding equipment

Automotive welding equipment (large size)

Off-line operation verification

Automotive welding equipment (medium size)

Actual machine photo

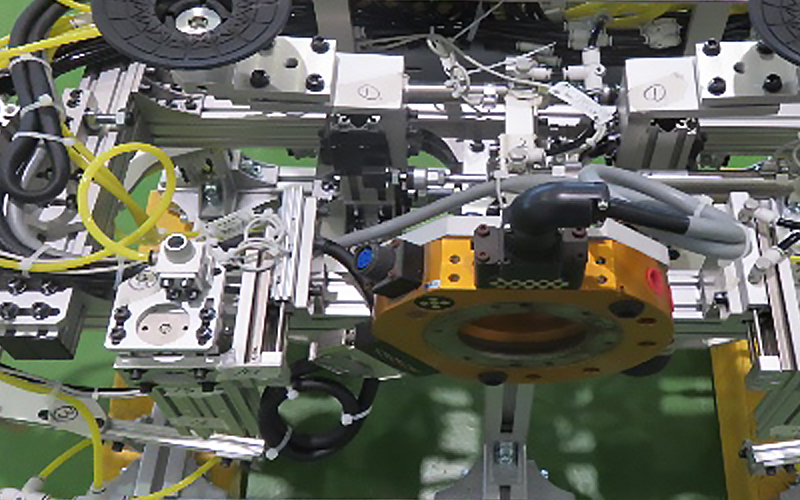

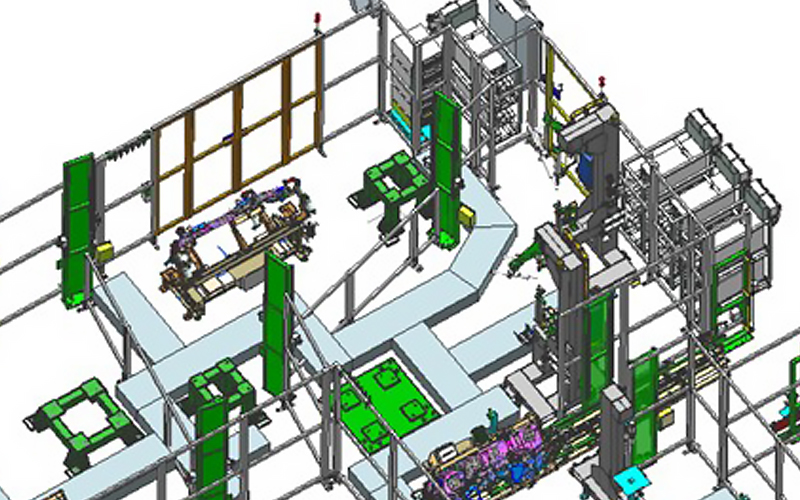

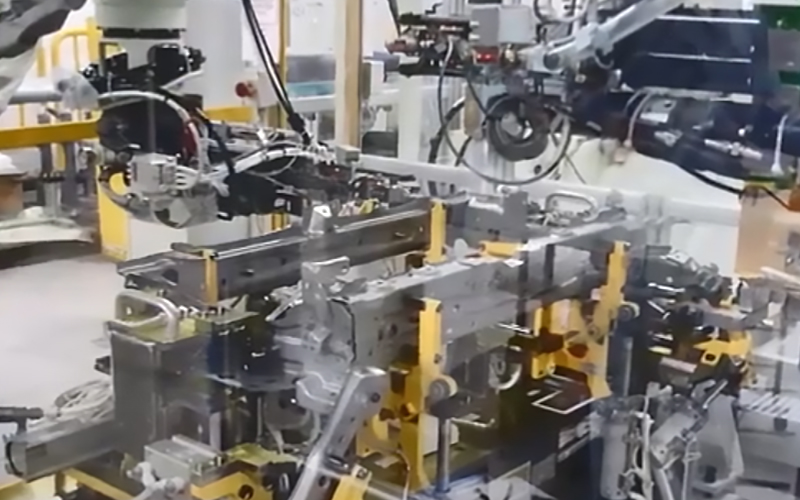

Case example 02

Bolted fastening + Handling

Bolt fastening + Handling automation equipment

Equipment overview

Actual machine photo

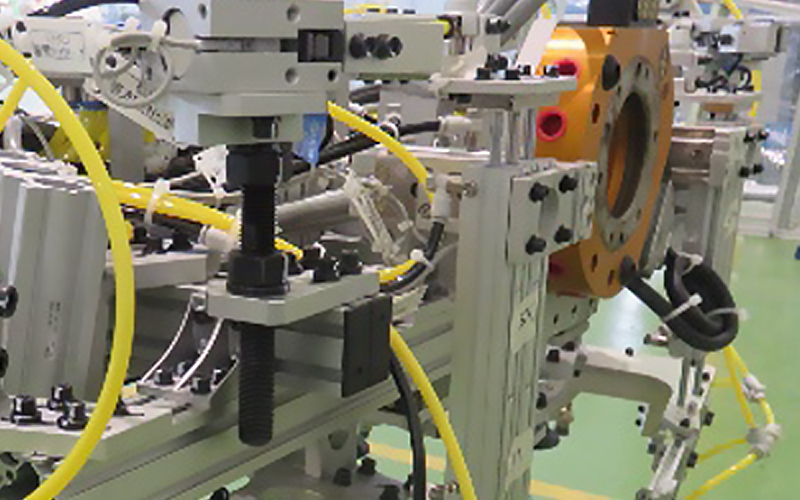

Case example 03

Automobile-related jigs

(rotating jigs)

(rotating jigs)

Rotating jig automation

Equipment overview

Actual machine photo

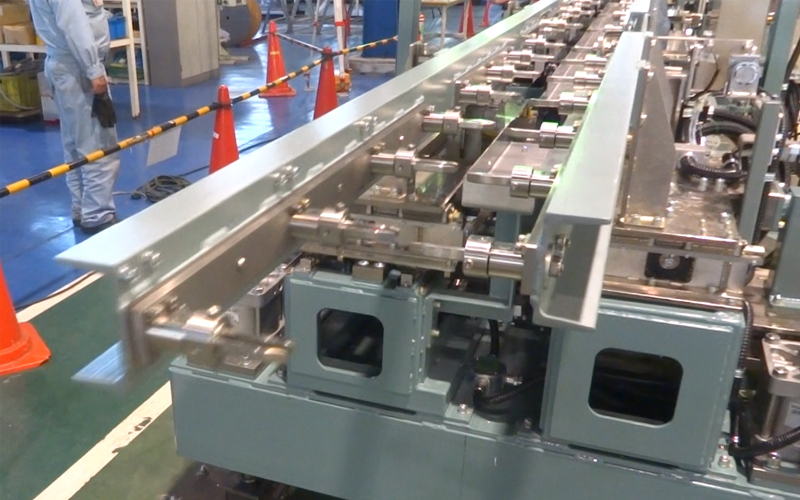

Case example 04

New transfer system for automobiles

(wire transfer)

(wire transfer)

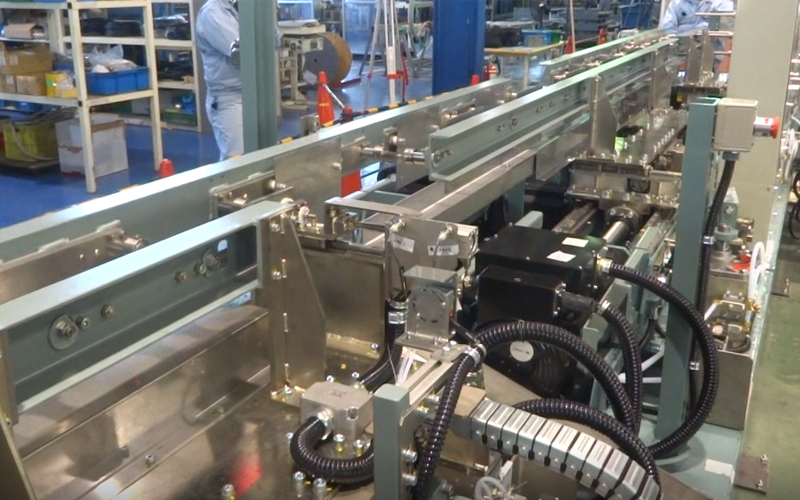

In-process transfer device (wire transfer with one motor)

Equipment overview

Actual machine photo

Case example 05

Auto parts equipment

Optimize the part line.

Device for press-fitting suspension parts

Dedicated machines ⇒ General-purpose machines

Actual machine photo

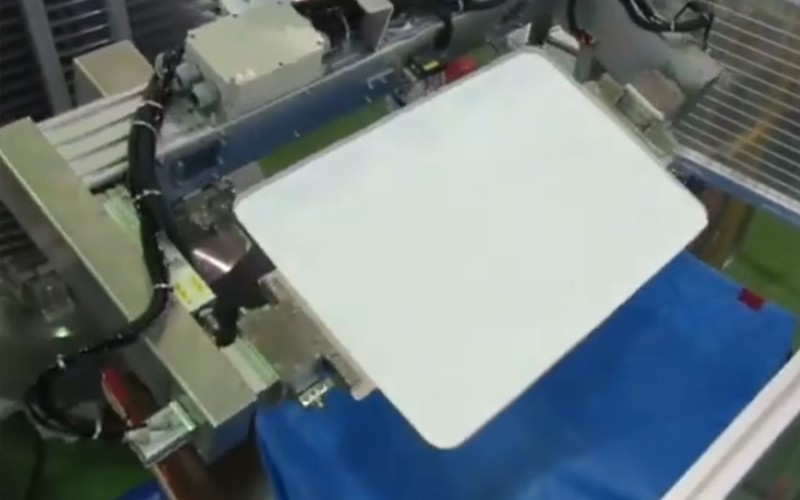

Case example 06

Primer application/

Heating furnace C/V

Heating furnace C/V

| Target work | Auto glass |

|---|---|

| introduction line | Primer application line before molding |

Actual machine photo

Case example 07

Auto glass equipment

(molding hand)

(molding hand)

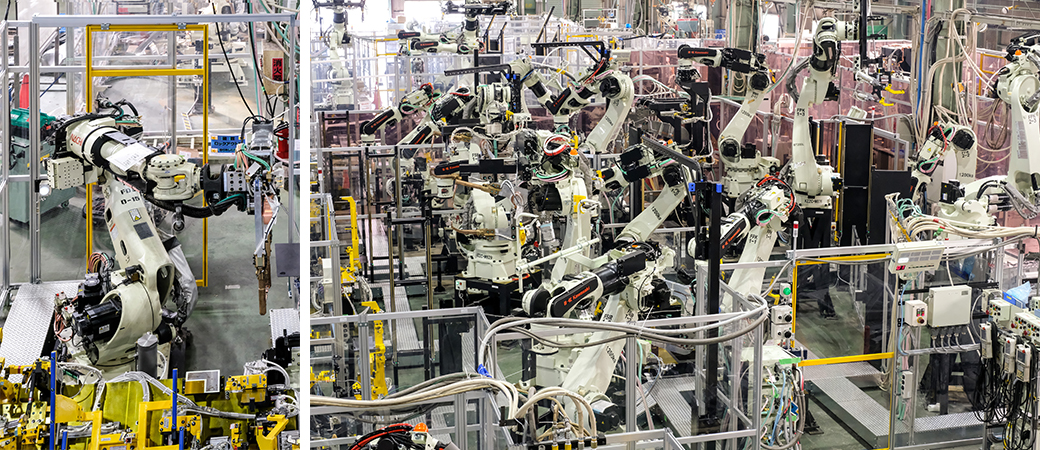

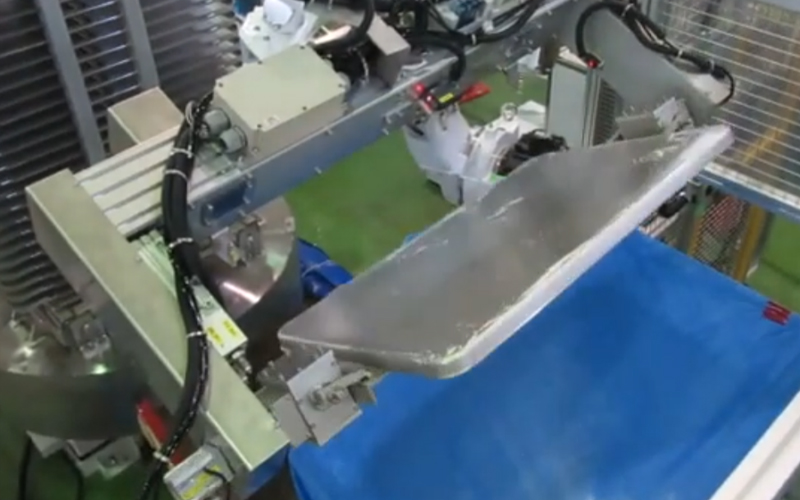

Automation equipment 08

Unmanned by robots

We succeeded in automating what workers used to do.

Case example 09

Conveyor/

Storage related

Storage related

Crescent storage conveyor

Buffer conveyor

F/F Extra hand conveyor

U/R Double-handed conveyor

Slat conveyor

Slat conveyor (side lifter)

Stock conveyor

(equipment delivered to North America)

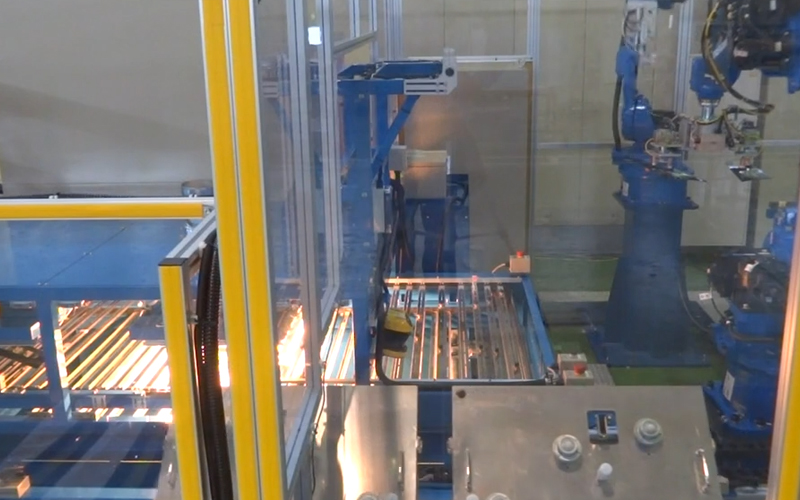

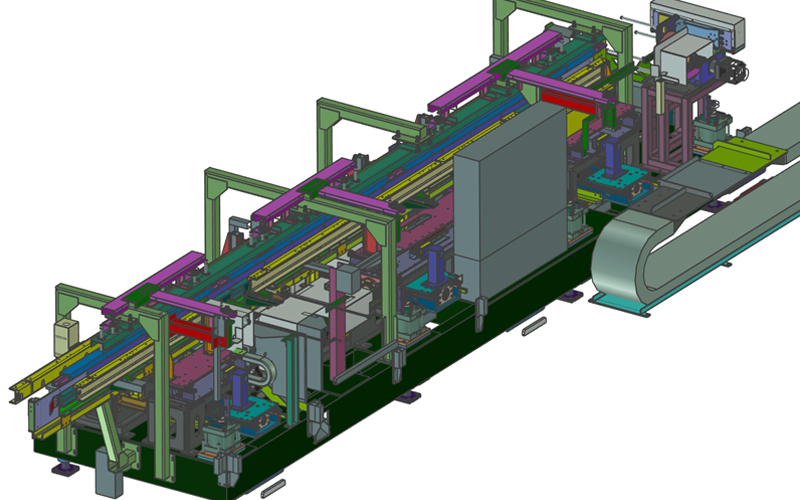

Automation equipment10

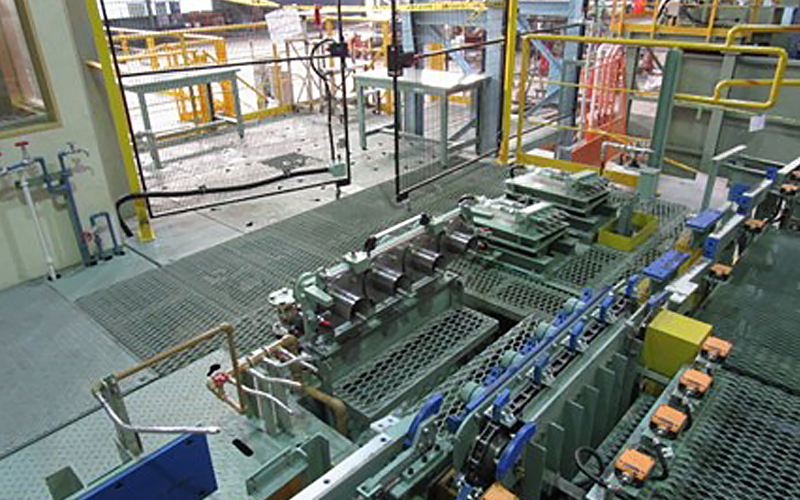

Steel production line equipment

Conveyor equipment

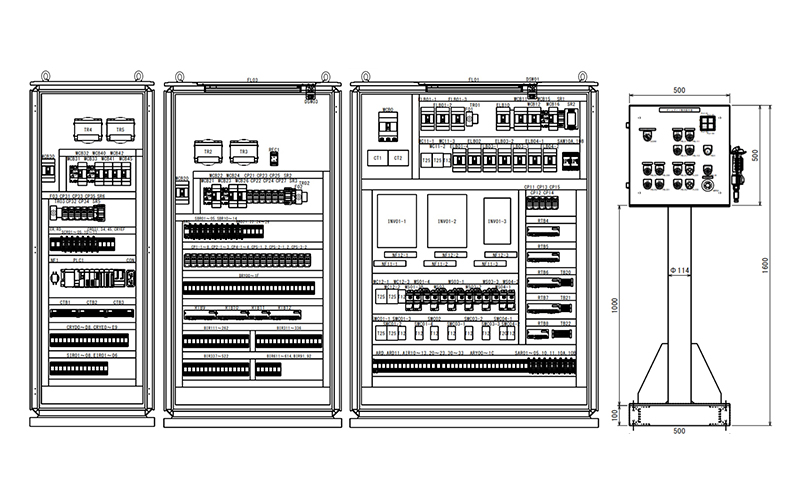

Equipment overview

- Total length 6m

- Equipment for pitch transfer (delivery transfer) of workpieces at approx. 1,000°C at 250 mm/1.2 seconds

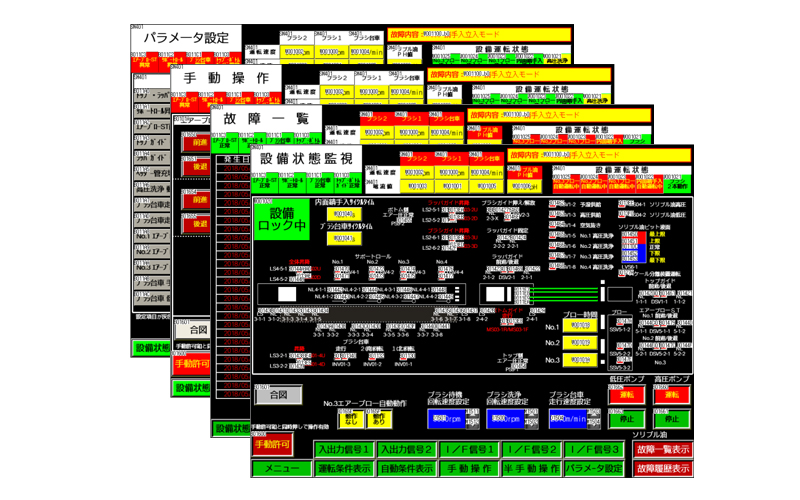

Electrical hardware design side (power/control panel, operation panel)

Actual machine photo

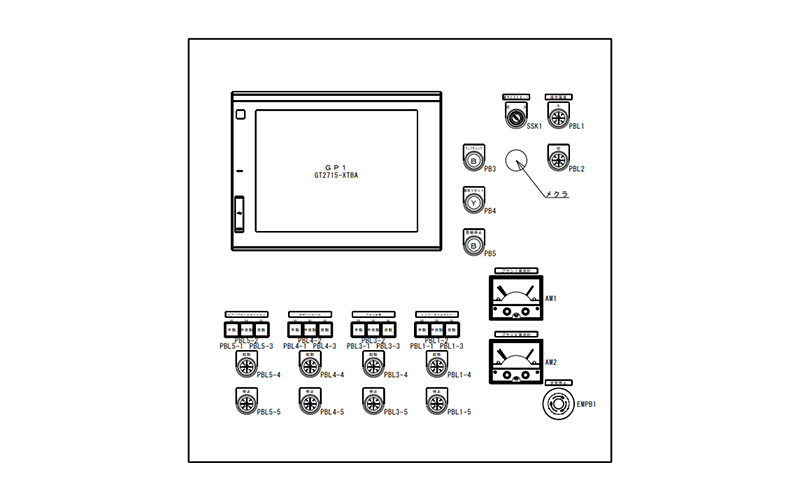

Electrical software design side (main operation panel, touch panel screen)

Actual machine screen

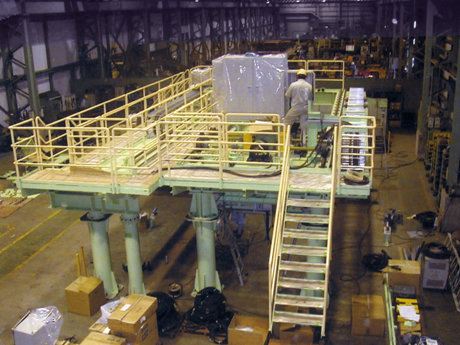

Mechanical/Electrical Package Project

Installation of internal rust treatment equipment

Conveyor line extension work

Ultrasonic probe

Ultrasonic probe

General products

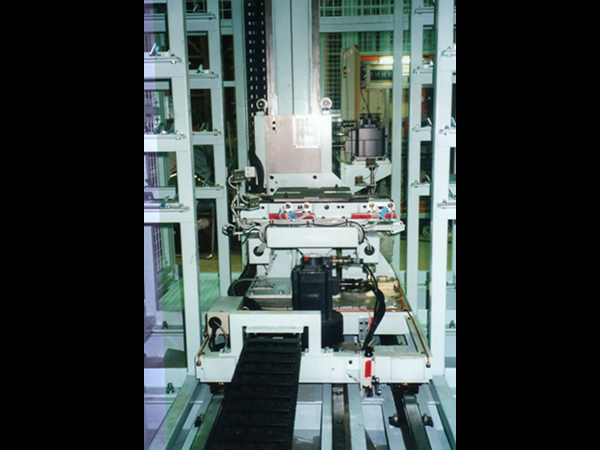

Automated warehouse for jigs

Automatic warehouse for jigs Internal stacker