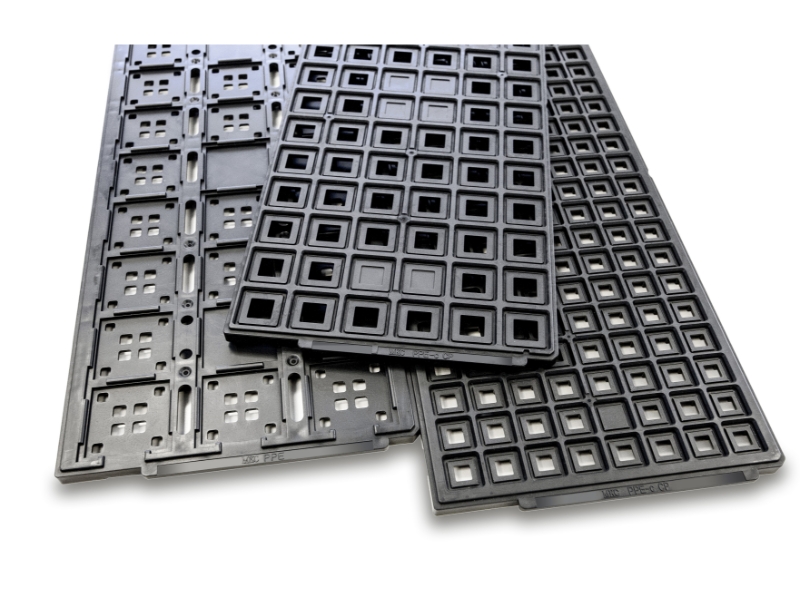

IC tray

We provide a one-stop supply service from resin composite pellet production

to tray product design, tray mold manufacturing, and tray molding in Japan

and overseas.

ISO9001 certified in 1996

ISO14001 certified in 2004

STEP FORWARD!

Manufacturing for a dreamy tomorrow,

bringing the smart Mishima brand more to the world!

Our IC tray business has developed from mold tooling technology. We respond to our customers' various specifications and requests with our advanced technology. Our combined monthly production capacity in Japan and overseas is 2 million pc/month, giving us the No. 1 market share in Japan at over 40%.

What is an IC tray (Semiconductor carrier tray)?

Semiconductors are used in all kinds of products, including cars and mobile devices. This IC tray is used in the transport and heat treatment of this semiconductor manufacturing process.

Point01

One-stop supply of high-performance,

high-quality products

through precision molding technology

high-quality products

through precision molding technology

In order to maximize the use and characteristics of the products requested by our customers, we provide a full range of services from material manufacturing, product design, mold design, mold manufacturing, and molding product manufacturing.

In product design, we perform optimal structural analysis and design, such as "design using 3D CAD" and "shape optimization proposal by flow analysis", to realize cost reduction through weight reduction and stability of "warpage and dimension" of products.

We also assist customers with quick development, including prototype requests.

IC tray production flow

Contribution to reduction of environmental load and realization of cost reduction!

Development and production of carbon fiber reinforced thermoplastic (CFRTP) using thermoplastic resin.

see more

Point02

Establishment of

an "integrated production system"

that carries out all processes in-house

an "integrated production system"

that carries out all processes in-house

1. Development and production of resin composite pellets

In-house production controls the quality of resin composite pellets, the molding material for IC trays.

Customization according to customer requirements and consideration of resin composite pellet development according to needs are also possible.

We develop and produce resin composite material pellets filled with carbon black and carbon fiber based on thermoplastic resins ranging from general-purpose plastics to engineering plastics.

We can also select resins and fillers according to customers' requirements and study the development of resin composite pellets.

Resin composite pellets for trays

| Resin | Usage |

|---|---|

| PPE + CP | General heat-resistant tray |

| PC + CP | Trays requiring good appearance |

| PSU + CF | Trays requiring rigidity/CP drop prevention |

Extruder

| Purpose | Screw | Japan (unit) | China (unit) | |

|---|---|---|---|---|

| Shaft | Diameter (mm) | |||

| For production | single axis | 110mm | 1 | |

| biaxial | 58mm | 2 | 1 | |

| For development | biaxial | 30mm | 1 | |

Twin screw extruder

Resin composite pellet

Twin-screw kneading extruder for development

Contribution to reduction of environmental load and realization of cost reduction!

Development and production of carbon fiber reinforced thermoplastic (CFRTP) using thermoplastic resin.

- Sliding parts

- Antistatic parts

- Electromagnetic wave shield parts

Product name

- FILFORCE (Trademark Registration No. 6537792)

- Philforce (trademark registration: No. 6537793)

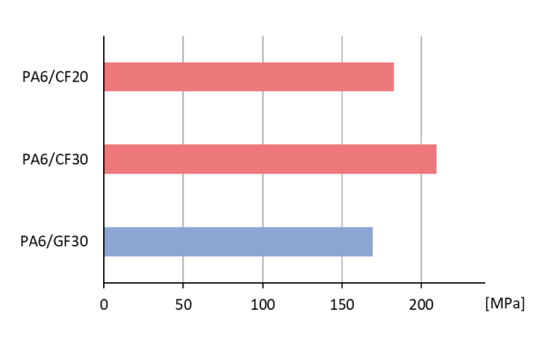

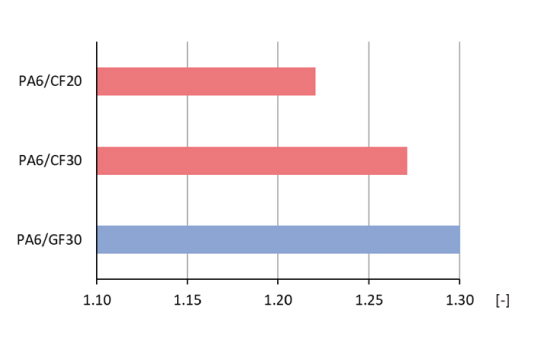

Compared to PA6/GF30, PA6/CF20 has equal or higher strength and lower specific gravity.

tensile strength

specific gravity

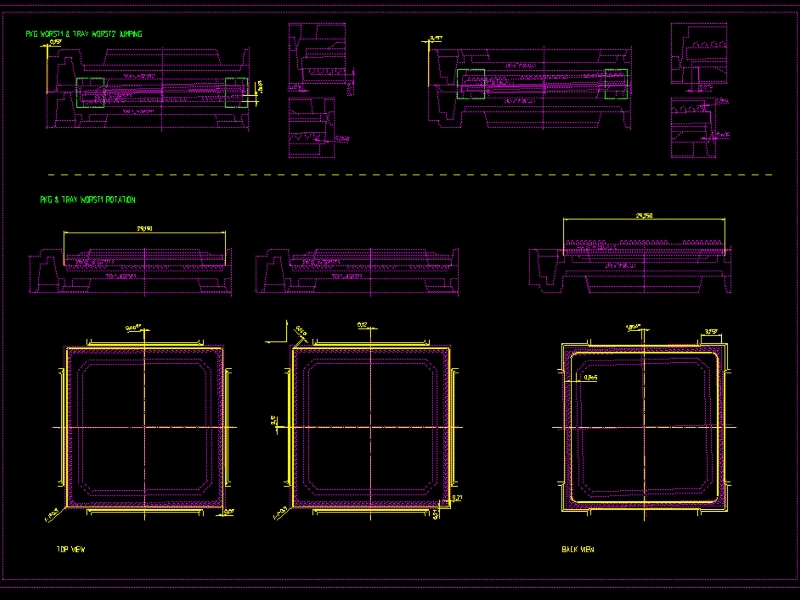

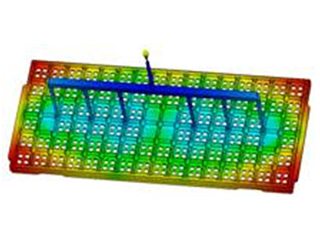

2. Mold design and flow analysis

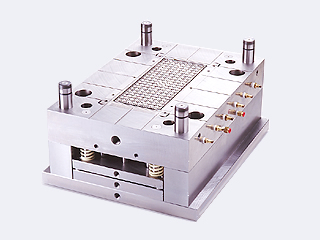

We design and manufacture high-quality IC tray molds based on mold design and analysis technology cultivated over 30 years.

Product design

IC tray resin flow analysis

Machining center

Machining center

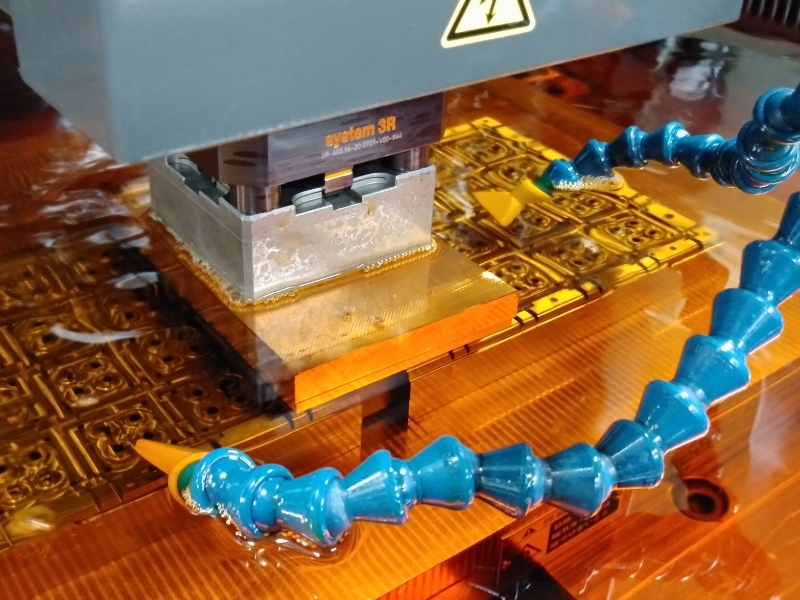

Die-sinker EDM

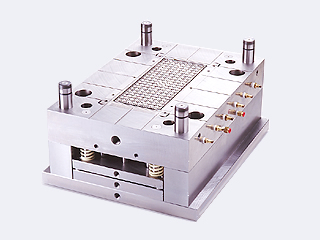

Injection mold

3. Injection molding

One by one production line from molding to annealing (heat treatment)

We have injection molding machines ranging from 50t to 350t in Japan and 180t to 250t in China. Utilizing the know-how we have cultivated over the years to our molding technology to build highly accurate, stable, and productive production lines to meet the needs of our customers.

Number of injection molding machines owned

| Clamping force (t) | Japan (unit) | China (unit) |

|---|---|---|

| 350 | 1 | |

| 280 | 1 | |

| 250 | 4 | 1 |

| 230 | 5 | 7 |

| 225 | 1 | |

| 220 | 3 | 2 |

| 180 | 1 | 2 |

| 50 | 1 | |

| Total units | 17 | 12 |

Plastic injection machine

Automatic warp measuring instrument

4. Measurement/Appearance inspection

Environment-friendly "manufacturing" with a perfect quality control system

The control center is located in Japan, and the products from the Chinese factory are also subject to a thorough quality control system.

In order to meet the demands of environmentally friendly customers, we are fully equipped with measurement devices and conduct surveys

on environment-related materials.

In particular, we use fluorescent X-ray analyzer to inspect environmentally hazardous substances, and we can also inspect each material lot

and lot of molded products.

X-ray fluorescence analyzer

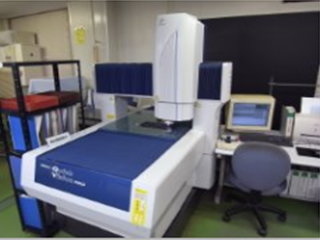

3D Measuring instrument (non-contact type)

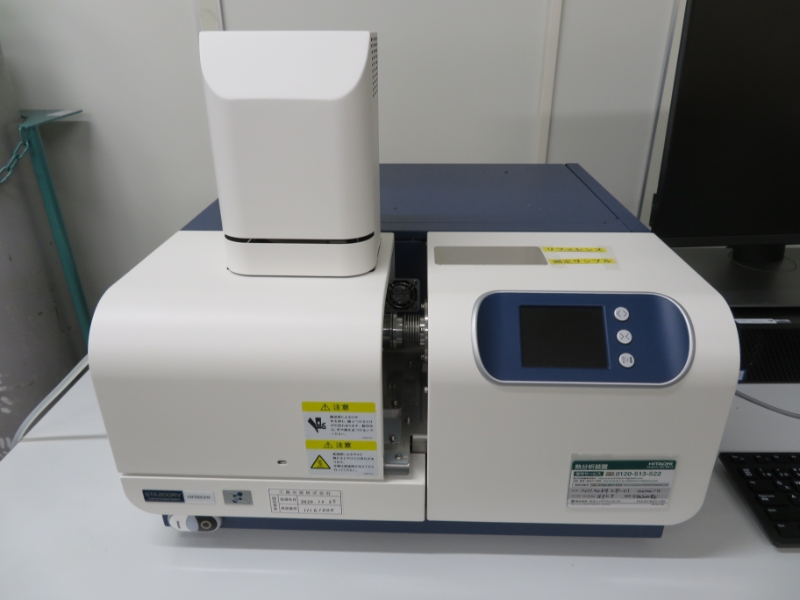

Differential thermal / Thermogravimetric simultaneous measurement device

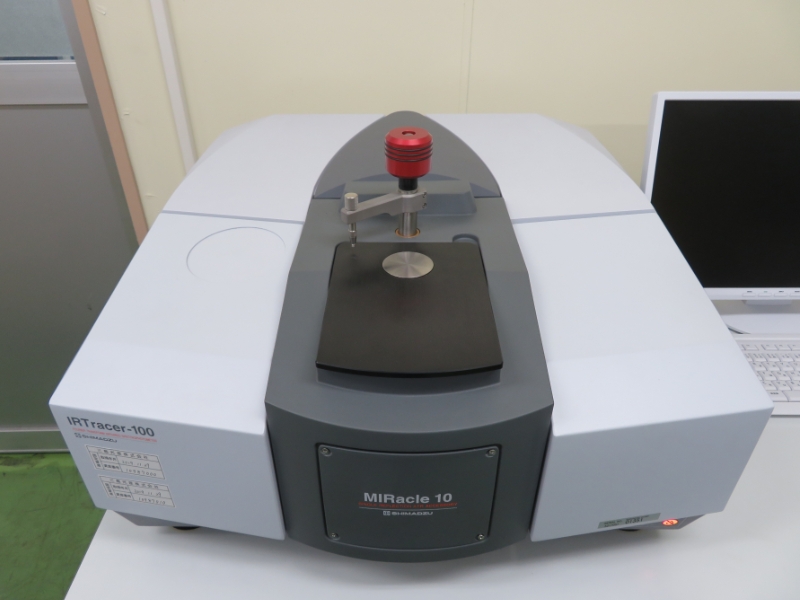

Fourier transform infrared spectrophotometer

Microscope

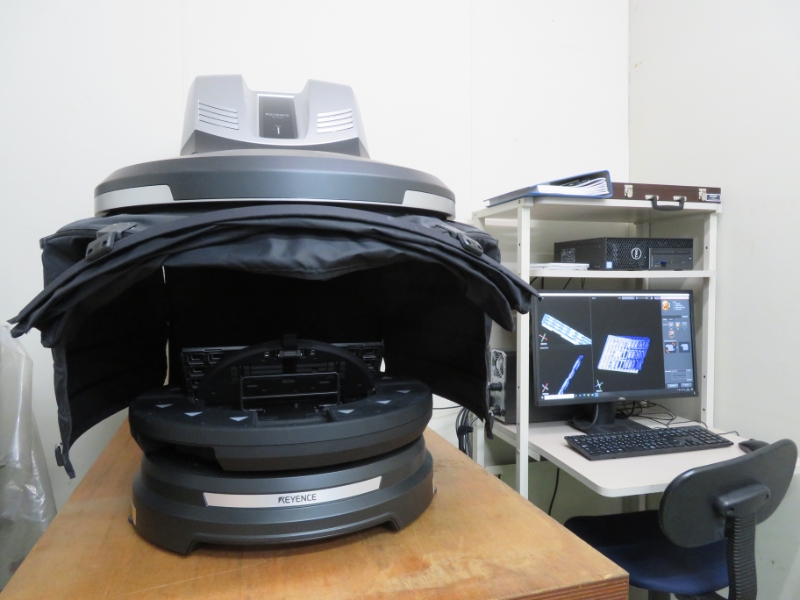

3D Scanner

Point03

Main product

Raw materials for IC trays

(resin composite pellets)

IC tray mold

IC tray

Point04

Major Customers,

Domestic locations, and Overseas locations

Domestic locations, and Overseas locations

Major customers

- Renesas Electronics Corporation

- Sony Semiconductor Manufacturing Corporation

- Amkor Technology Japan Co., Ltd. other

Domestic locations, overseas locations

Domestic locations

Sales locations

- Tokyo Sales Office

7F No.2 Toyo Building, 2-1-21 Nihonbashi, Chuo-ku, Tokyo 103-0027

TEL : +81-3-3548-0551 FAX : +81-3-3273-1957

Production sites

- Precision Molding and Mold Department

5-1 Shinsone, Kokuraminami-ku, Kitakyushu, Fukuoka 800-0211

TEL : +81-93-472-4222 FAX: +81-93-471-7144

Overseas location

Sales locations

- Mishima Kosan Precision Plastics (Dongguan) Co., Ltd. Shanghai Sales Office

- Mishima Kosan Hong Kong Co., Ltd. (Hong Kong)

Production sites

Search in detail

Solution / Technical information

Main facility list

Main facility list

Here is a list of the main facilities we own.