Strength of Mishima Kosan 2

Large surface treatment

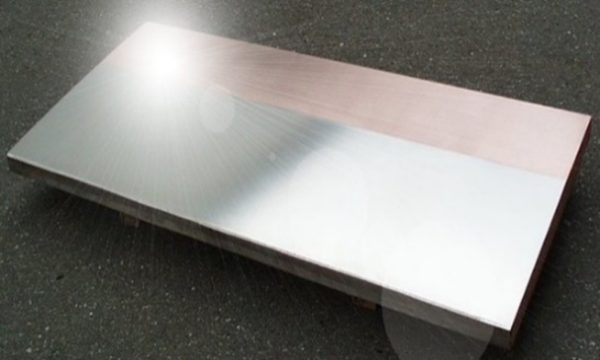

We have a wide range of surface treatment technologies such as electroforming, plating, and thermal spraying that can handle upsizing with cutting-edge coating technology.

Molds used under severe conditions will suffer damage specific to each part.

We can provide detailed examination of copper plates after use, and propose the selection of coating materials and design that best suits each customer's needs, thereby extending the life of the molds.

Large surface treatment

Point01

Wide variety of coatings

for various applications

for various applications

Propose the best coating

We propose the optimum coating for continuous casting mold surfaces using large-scale electroforming and thermal spraying equipment.

| Plating (electroforming) | Ni, Ni alloy, CoNi alloy, Cu, Cr |

|---|---|

| Thermal spray | NiCr alloy, cermet |

| Electroless plating | Ni |

Owned equipment information

Electroforming equipment

| Type | Number of tanks | Plating tank maximum size | ||

|---|---|---|---|---|

| length | width | height | ||

| Co-based plating bath | 11 tanks | 3,400 | 610 | 1,820 |

| Ni-based plating bath | 8 tanks | 3,400 | 610 | 1,740 |

| Cu plating tank | 1 tank | 3,300 | 625 | 1,440 |

| Cr plating bath | 4 tanks | 3,800 | 690 | 1,500 |

Thermal spray equipment

| Type | Number of facilities |

|---|---|

| JP-5000HVOF | 2 units |

| TASNAC-XRC-UP130 | 2 units |

Search in detail

Solution / Technical information

Main facility list

Main facility list

Here is a list of the main facilities we own.