Process contract

Process contract at Auto glass and building material factories

our comprehensive technical capabilities.

At AGC Corporation (hereafter, AGC) Sagami Plant, we undertakes the automotive glass manufacturing lines as main business partner. At AGC Kashima Plant, we support residential building materials production line at Asahi Tostem Exterior Building Materials Co., Ltd.

Contract case examples

Case example 01Automotive glass related

Case example 02Building materials

Case example 03Logistics

Our company's automotive glass and building material related plant Process contract are carried out at two locations , the AGC Kashima and Sagami Plant , and employs approximately 240 people.

Received many AGC “Supplier Awards President’s Awards”!

Each year, the President's Award is presented to a cooperating company that has made a significant contribution to AGC's business among the hundreds of AGC's business partners. Mishima has received the award five times, and

it is a great honor for the company to be recognized for its comprehensive efforts in cooperation with AGC.

AGC Co., Ltd. President Award History

- 1981 System inauguration first commendation (Chiba Department)

- 1982 Kashima Department

- 1984 Former Kitakyushu Division

- 2009 Chemical Works Headquarters

- 2015 Chemical Works Headquarters

Received a letter of appreciation from Asahi Tostem Exterior Co., Ltd.

We received a letter of appreciation from our customers for our proactive efforts to improve quality and reduce manufacturing costs, as well as our efforts to detect abnormalities before they occur and prevent them from causing trouble.

Received a certificate of commendation from the General Sagami Plant of AGC Co., Ltd.

We received a "special award" from the manager of Sagami Plant for contributing to quality improvement and production efficiency improvement through efforts to reduce work-in-process inventory, improve the number of processed products, and work to improve the work of large special glass.

Case example 01

Automotive glass related

Sagami Department

As a customer's main business partner, we undertake a wide range of processes for automotive glass production lines.

Target business department

Sagami Department : Glass processing/Auto glass

Strengths of Mishima Kosan

Full training and support system to deliver safety and security to customers

- One-on-one education by senior employees

- Inspection work training uses eye tracers to provide detailed guidance to senior employees and their own eye movements.

- Create and install a procedure manual for each work that anyone can understand. Each person can review and prepare for work at any time.

Production planning and material glass preparation

We work backward from the customer's desired delivery date to create

a production plan. We prepare material glass in time for production.

Material glass preparation

Manuals always nearby

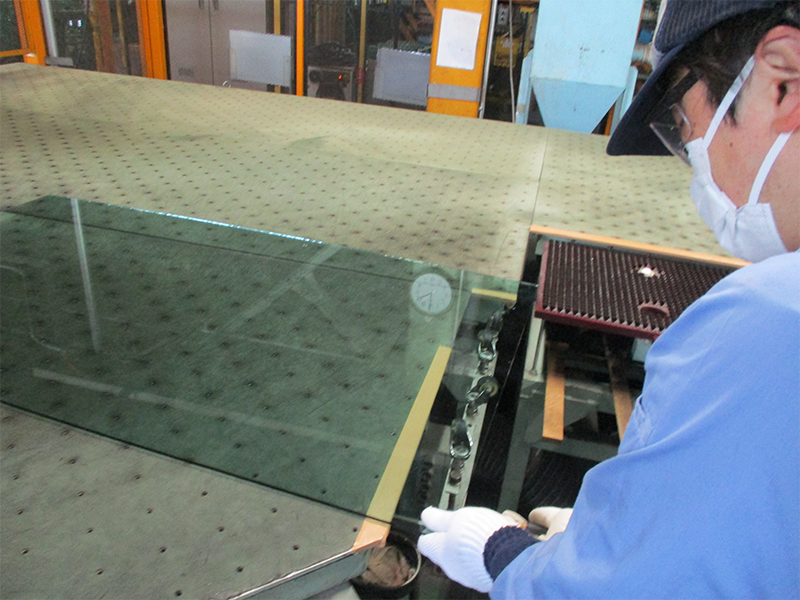

Material glass processing

Cutting and folding is performed according to the shape of automotive glass to prevent chipping.

Glass processing

One-on-one education

by senior employees

Appearance inspection

In the appearance inspection, we perform a 100% inspection of

the finish of the outer circumference, scratches and stains on the surface.

Inspection

Newcomers are supported

by senior employees

Packing and on-site logistics

In the final process, the product is packed according to the customer's request and transported to the designated warehouse by forklift.

Packing

Shipping

Case example 02

Building materials

Kashima Department

We undertake a wide range of processes for manufacturing exterior wall materials for housing with design characteristics.

Target business department

Kashima Department : Building materials/Residential exterior wall materials

Injecting and blending the raw materials necessary for manufacturing according to the customer's production plan

We mix cement, silica sand, valves, etc. necessary for manufacturing exterior wall materials for housing.

Pulp

Responsible for a series of manufacturing processes for exterior wall materials for housing

We are in charge of the manufacturing operation (operation) of housing exterior wall materials.

We systematically provide education on the basic knowledge necessary for manufacturing operation and processing, as well as education on the structure and mechanism of processing and operation equipment, and develop operators who contribute to stable production by improving safety and quality.

Kashima Department

Inspection/Analysis

We inspect and analyze our products to ensure that they are delivered to our customers in accordance with their quality and specifications.

Kashima Department

Packing

We check and pack exterior wallboard materials for housing to ensure that the product type and quantity are sorted as requested by the customer and that there are no defects in the product.

Kashima Department

In-house logistics/Shipment

Responsible for the storage and shipping of exterior wall materials manufactured at the building material factory to the warehouse. We are in charge of shipping from the warehouse to customers all over Japan and overseas. We are working to reduce the burden on the crew by streamlining the transportation method.

Case example 03

Logistics

Target business department

Kashima Department : Building materials/Residential exterior wall materials

Confirmation of product types, quantities, sorting, and presence of defects as requested by the customer

We are responsible for receiving and shipping of raw materials, inventory management of various equipment, storage and delivery work, and plays a pipeline role to ensure smooth operations between each process.

We also respond flexibly to urgent correspondence and troubles from users.

We manage quality and productivity as a command post to the field.

Kashima Department

Kashima Department

Responsible for on-site transportation operations such as storage and shipping of exterior wall materials manufactured at the board factory

We are committed to safe and secure transportation, and efficiently transport our customers' important products.

The Kashima Department is in charge of logistics center operations for residential exterior wall materials.

From warehousing and management of products to shipping throughout Japan and overseas.

By adopting our systemization proposal, we are contributing to significant improvement in work efficiency and reduction of the burden on transport crews.

Kashima Department

Main facility list

Main facility list

Here is a list of the main facilities we own.