Process contract

Process contract at

Steel works

achieve efficiency in steel production lines with solid trust and

Mishima's comprehensive technical capabilities!

At Steel works, not only are there huge facilities such as blast furnaces and continuous casting, but all of the machines and parts for each process function accurately to deliver high-value-added steel products to society.

Based on the steel refining and processing technology we have cultivated over the years, we provide contract work on steel production lines as a business partner of the Nippon Steel Corporation Group, the world's No. 1 steel manufacturer.

Team Mishima brings together its comprehensive strengths, works to improve equipment and operational technology, and supports customers in the realization of safe, highly productive, and high-quality steel products.

Contract case examples

Case example 01Manufacturing process of thick stainless steel thick plates

Case example 02Thick plate manufacturing process

Case example 03Thin plate manufacturing process

Case example 04Manufacturing process

and the number of our employees

We have two locations for process contract, Kimitsu and Yahata factory, where about 750 employees are working.

Manufacturing sites of Nippon Steel Group and our contract

Early reduction of the risk level in the thick plate slab yard movable area

In order to reduce the risk level in the movable area of the thick plate slab yard at an early stage, we cooperated with the maintenance group without compromising safety measures, and achieved the goal with various countermeasures!

Participate and support the project. Received Nippon Steel Corporation Technical Development Headquarters Business Award!

We have established procedures for pretreatment of specimens and oxidation test work, chemical structure analysis, and data analysis using newly introduced equipment, and have contributed to the acceleration of analysis by proactively implementing operations and achieving sufficient results. We have received high praise from our customers.

Received a letter of appreciation from the General Manager of the Manufacturing Division of Nippon Steel Stainless Co., Ltd.

"Achievement of a new record for total heat treatment throughput"

The Yahata Department received a letter of appreciation from the customer for its contribution to setting a new record for throughput by providing operational support such as streamlining logistics.

Achieved a record of zero-schedule delay in a row in bridge auction orders witnesses! Received Nippon Steel Corporation's thick plate General Manager's Commendation

We have contributed to the improvement of the alignment rate by managing express materials in the process, including direct cooperation on a daily basis, and achieved no schedule delay for five consecutive years.

Case example 01

Manufacturing process

of thick stainless steel plate

of thick stainless steel plate

Subject: Yahata Department

For more than half a century, we have been in charge of finishing and ancillary work as a partner company at Nippon Steel Stainless Steel Co., Ltd.'s

thick plate plant located in the Yahata area of Kyushu Steel works, one of the world's leading stainless steel plate manufacturing locations.

Slab conditioning work before rolling

- Grinding of slab surface

- Gas cutting to the heating furnace input size

- Assembling clad steel slabs

Hydraulic straightening

After rolling, the flatness of the steel plate is adjusted by a hydraulic straightening machine.

Hydraulic straightening

Plasma cutting

The steel plate is cut to the dimensions specified by the customer using a plasma cutting machine.

Plasma cutting

Grinding

Polish the surface of the steel plate to the specified surface roughness with a wet polishing machine.

Grinding

Packing and shipping

Steel sheets that pass the Inspection are packed according to the customer's specifications and shipped.

Packing

Shipping

Case example 02

Thick plate manufacturing process

Subject: Steel Plate Department

Responsible for work directly related to the plate manufacturing line and ancillary work

at the plate plant in the Kimitsu area of Nippon Steel Corporation.

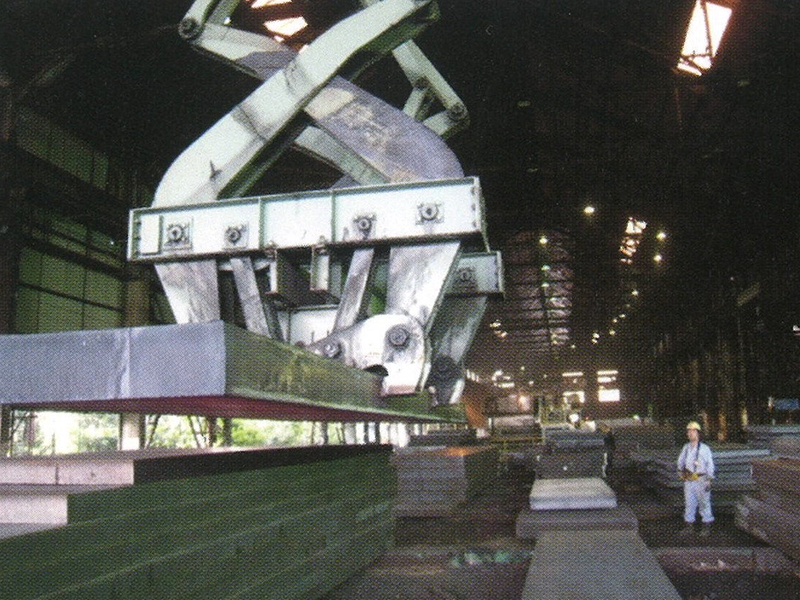

Photo: Nippon Steel

Furnace supply

Slab reception/Cutting/Furnace supply

Slabs (steel billets) manufactured in the steelmaking process are received in the yard by crane and gas-cut to size to be supplied to the heating furnace.

The cut slabs are supplied to the heating furnace by crane according to the production plan.

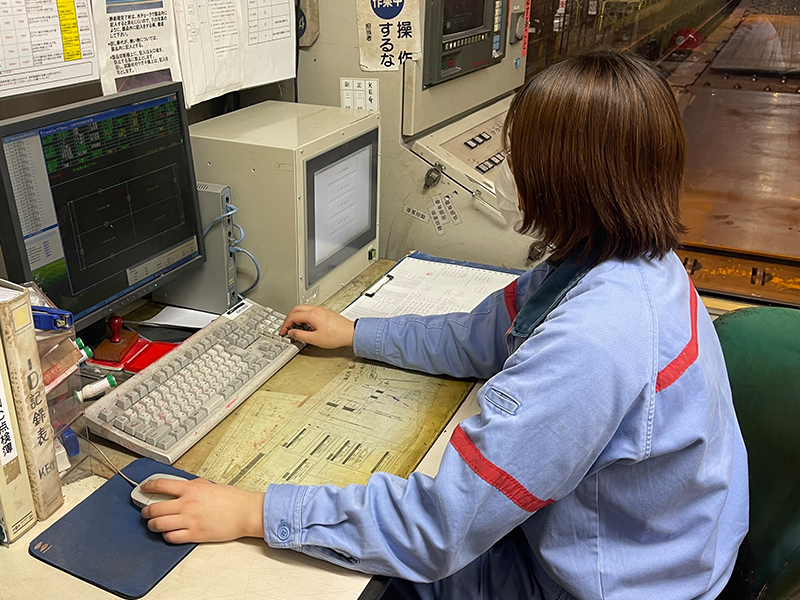

Yard operation room

Steel plate gas cutting

Gas cuts the rolled steel sheet into user-specified shipping sizes.

Numerically controlled equipment is used for gas cutting (drawing guide lines for cutting) and gas cutting.

(Cutting method: gas cutting, plasma cutting)

Marking-off operation room

Steel sheets that pass the Inspection proceed to the specified process,

or to warehousing and shipping.

Steel sheets that do not meet the shipping standards are added to the steel sheet refining process, and are corrected and repaired to meet the standards.

(correction, maintenance, etc.)

Steel plate finishing process

- Steel plates that deviate from the standard due to flatness (shape) reasons are corrected to become flat steel plates.

- For steel sheets that do not meet the standards due to surface defects, harmful defects are manually removed.

- The steel plates added to the steel plate refining process are re- Inspection after finishing the refining process, and the steel plates that pass the process proceed to the next process.

Corrective work scenery

Painting

If specified by the user, coating is applied to the front and back surfaces of the steel plate for primary corrosion prevention.

Painting scenery

Case example 03

Thin plate manufacturing process

Subject: Steel Plate Department

Responsible for work directly related to the steel sheet manufacturing line and ancillary work at the hot-rolling mill and cold-rolling mill in the Kimitsu area of Nippon Steel Corporation.

Photo: Nippon Steel

Receiving slabs and supplying heating furnaces

Slabs (steel billets) produced in the steelmaking process are received in the yard by crane. The received slabs are supplied to the heating furnace by crane according to the manufacturing plan. The crane moves remotely and automatically.

Slab transport by crane

Maintenance of rolling rolls

We disassemble the rolling rolls used for rolling and polish the used rolling rolls. Polished rolling rolls are reassembled and reused for rolling. We also maintain parts other than rolls after disassembly. (Grinding about 100 rolls/day)

Rolling roll polishing

Bearing maintenance

Case example 04

Manufacturing process of small diameter pipe

Subject: Steel Pipe/Steel Products Department

Responsible for work directly related to the pipe-making line and the finishing line at the small-diameter pipe plant in the Kimitsu area of Nippon Steel Corporation.

It adds value to the pipes manufactured on the pipe-making line and plays an important role in maintaining quality.

Heat treatment

Since the structure and strength of the pipe base material and the joint (welded part) are different, heat is applied to make the structure and strength uniform. Strict temperature control is required.

- Loading and unloading pipes using an overhead crane

- Temperature control of bright furnace

Correction

A straightening machine is used to straighten any bends in the pipe that were created during the manufacturing process.

- Reorganization and adjustment of straightening machine

- Bending measurement after straightening

(ET/UT)

Nondestructive Inspection(ET/UT)

UT (ultrasonic waves) and ET (eddy currents) are applied to the pipe and the projected waveforms are used to inspect for flaws and weld defects.

Expertise in reading the waveforms is required.

- Replacement and adjustment of flaw detector

- Checking inspection results

Inspection work

Cutting

Cut the pipe to the length required by the user. A chamfering machine is used to polish the burrs (cut ends) at the pipe ends created during cutting.

- Cutting machine setting, grindstone replacement

- Rearrangement of chamfering machine

- Operation monitoring during adjustment and continuous operation

Cutting work

Cutting work

Inspection

We measure and Inspection the pipe diameter, wall thickness, and length at

a specified frequency, and conduct a strict visual inspection of the pipe appearance and inner surface one by one.

- Measure pipe diameter, wall thickness and length

- Visual Inspection of pipe appearance and inner surface

Printing/Painting

A special paint is used to print on the body. Due to temperature and humidity changes, it is necessary to fine-tune the paint composition.

In addition, a rust inhibitor will be applied to the entire pipe to prevent the pipe from rusting.

- Printer settings and adjustments

- Sprayer settings and adjustments

- Operation monitoring during continuous operation

Packing and bundling

After forming the specified number of tubes, the ends and bodies of the tubes are wrapped in special packing materials to prevent scratches, dents, stains, rust, etc. during storage and transportation.

- Molding machine settings and adjustments

- Packing and bundling of pipes

Shipping

To transport by land (truck) or sea (ship), products are loaded onto truck carts or carts (pallets) to be transported to ships.

- Pre-shipment Inspection of products

- Loading onto a carts by an overhead crane

Supports stable operation

Maintenance

In order to ensure stable plant operation, we support the production lines at our customers' plants by making full use of our long-accumulated technology and

know-how, and we also leverage our comprehensive technological strengths to contribute to the improvement of our customers' manufacturing capabilities.

We support the stable operation of the plant as a partner company by updating and repairing facilities, inspecting equipment and facilities, etc.

Main facility list

Main facility list

Here is a list of the main facilities we own.